By Jim J. Spiegel

By Jim J. Spiegel

It comes as no surprise that digitization is transforming all industries. And as an industry-leader chemical product selection and information management platform, UL Solutions sees this transformation evolving daily within the chemical industry. Based on these learnings, we’re pleased to kick off a four-part educational series focused on Digital Transformation in the Chemical Industry. This series will cover industry trends, digital asset consumers, digital asset providers, and what may be in store for the future of digital transformation.

If you’re reading this material, there’s a good chance you have witnessed first-hand the tongue-twisting articulation of colleagues or clients explaining digitization, digitalization, and digital transformation. To level-set terminology as we navigate this series, we’ll start with a brief definition of each of these stages in the transformation journey:

Digitization: In its simplest form, this is the process in which analog information is converted or captured in digital format. The primary objective of this stage is to create actionable or accessible information that can be shared at scale. A basic everyday example would be capturing meeting notes in a word processing program compared to having them handwritten in a notepad.

Digitalization: These are the automation efficiencies created through access to digitized content. To continue the word processing analogy, Google Docs provides a great example of how digitalization can offer real-time collaboration across many colleagues in any part of the world.

Digital transformation: The impacts of both digitization and digitalization can result in a digital transformation for a business. Digital access to all your company’s content can revolutionize your operations – creating organizational efficiencies, speeding research and consolidating resources – ultimately delivering value to your customers. It can be a complete game changer for the workflow as old habits are broken, and new methods are realized.

As we’re finding in 2023, this stage of the journey requires a tolerant culture for change and a true growth mindset. This is on full display with the current state of Artificial Intelligence relative to our example of digitizing notes. AI can now access ALL written word available online or within an organization and provide user interactions with these digital assets that mimic human neurological outputs.

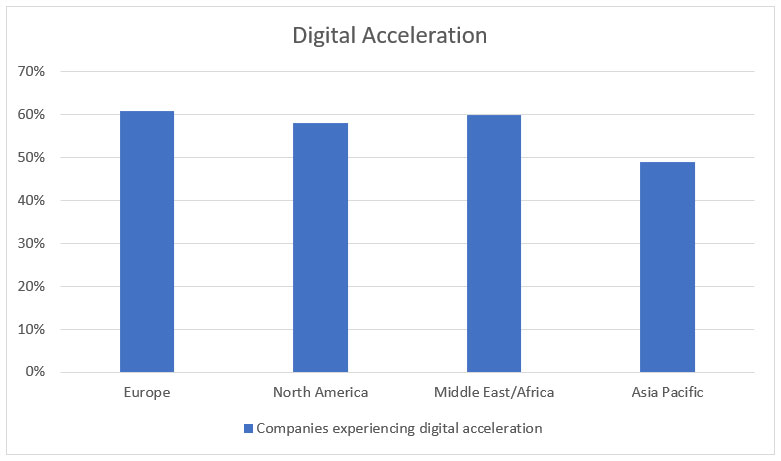

In the DigiChem SurvEY 2022 report published by EY, 637 respondents representing top management members and executives from various segments and sizes of chemical companies provided insights on the impacts of digitalization in the chemical industry. 56% of respondents reported that the speed of digitalization has accelerated following two years of COVID-19. A clear takeaway is that the majority of chemical companies realize digitalization is rapidly transforming the chemical industry with a significant impact on supply chain efficiency, innovation, and development.

‘What impact do you expect digitalization will have on your company in the next three years?’ |

‘To what extent digitalization will affect the success of the strategic and operational positioning of your company in the next three years?’ |

|||

| Revolutionary or Disruptive | 65% | Innovation and Development | 68% | |

| Processes and efficiency in operational supply chain | 63% | |||

Turning to Deloitte’s 2023 Chemical Industry Outlook, one of the four core trends is Emerging technologies drive value chain improvements and sustainability. The report frames the implementation of digital transformation objectives as an opportunity for chemical companies. “The smart factory of the future for the chemical industry converges the OT, IT, and IIoT systems leveraging Industry 4.0 and integrates supply chain and operations siloed across planning, scheduling, manufacturing, logistics, and asset management operations execution functions. The resulting integrated operations facilitate dynamic and collaborative response and resolution of real-time adverse operations events for optimal value realization across the value chain.” Harmonized and completely digitalized data sources are the foundation for building a fully digitized supply chain. Digital data is the key to achieving these improvements and sustainability.

No one in the chemical industry needs to search far to find reputable industry reporting on the impacts and opportunities that digital transformation objectives offer. However, as with all things digital, the devil is in the details. Where does your organization begin? In a McKinsey report, Digital in chemicals: From technology to impact, an organization must “Create a clear target picture. Senior management needs to define where it sees the company in the future with respect to digital. (…) The target picture needs to answer these questions: In which ecosystems and at what position in the value chain do we want to play? What is the greater goal: operating efficiency or increasing revenue? What are the focus areas across the business model, the customer-facing front end, products, and operations?” As gathered from these reports, many companies see the importance, the opportunity, and the need to create a centralized plan.

What stage of digital transformation is under way at your organization? Whether you are in the process of digitizing written laboratory notes or well along the path to centralized data harmonization, the need to collaborate cross-functionality has never been greater. Each cog in the supply chain plays a vital role in this process. Within UL Solutions, we work daily to achieve digital transformation objectives and deliver digital transformation solutions to customers and members. We welcome and look forward to navigating digital transformation roadmaps together!

References

- 2023 Chemical Industry Outlook | Deloitte US (cited)

- Digitalization is transforming the chemical industry | EY – Global (cited)

- Digital in chemicals: From technology to impact | McKinsey

Learn more about UL Solutions data integration services to help your organization with its digital transformation.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.