Carbon Black pigments have been used for millennia and provide a multitude of benefits. Features include not only a profound impact on opacity, but are effective UV-visible light absorbers, provide resistance to oxidation and reduce chalking. Lastly, Carbon Black pigments are versatile and are available in a number of variations and qualities which vary in their particle size, manufacturing process and ease of dispersion. Carbon Black is widely used as a pigment in paints, coatings, plastics, and rubber as it provides a higher tint strength and a deeper black color and greater tinting strength when compared to iron black or organic pigments.

Carbon Black pigments have been used for millennia and provide a multitude of benefits. Features include not only a profound impact on opacity, but are effective UV-visible light absorbers, provide resistance to oxidation and reduce chalking. Lastly, Carbon Black pigments are versatile and are available in a number of variations and qualities which vary in their particle size, manufacturing process and ease of dispersion. Carbon Black is widely used as a pigment in paints, coatings, plastics, and rubber as it provides a higher tint strength and a deeper black color and greater tinting strength when compared to iron black or organic pigments.

Carbon Black utility – Carbon Black pigment usage dates back over 2,000 years to the early Egyptians, Chinese, and Indian civilizations. Fast forward to the early 1900’s when Ford quickly found out that the most durable color was black and in 1914 determined that was the only color that would be available. The paint was comprised of Tung oil and a carbon black Gilsonite dispersion. A Carbon Black based paint not only absorbs over 99% of light, but the surface of many Carbon Black pigments contain a high level of aromatic rings and phenolic groups which act as antioxidants that also enhance the weather resistance of Carbon Black based paints. Due to its high tint strength, Carbon Black is the most common pigment used in conjunction with titanium dioxide. Due to its efficiency in blocking UV/visible light, a low level of carbon black not only enhances weather resistance in a topcoat, but when used in a topcoat also decreases light transmission to the primer surface and helps to prevent loss of topcoat adhesion to the primer (especially with epoxy-based primers). Carbon Black pigments are also used in to enhance efficiency and life expectancy of solar panels as they effectively absorb sunlight across the light spectrum that combined with its electrical conductivity, makes it a valuable component in photovoltaic technology. By reducing the amount of reflected light coupled with its electrical properties enables carbon black to provide greater energy output.

Explore the ULTRUS Portfolio supporting regulatory, supply chain and sustainability needs. Learn more here!

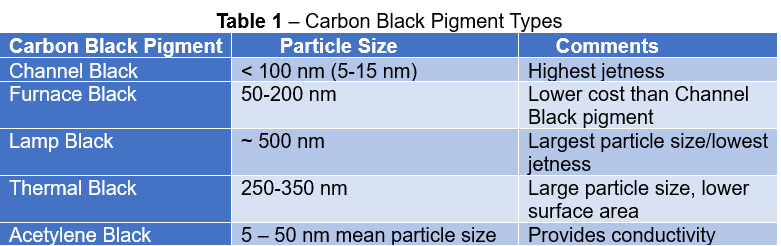

Manufacturing Process – Most Carbon Blacks are made by a variety of manufacturing processes which utilize partial combustion of petroleum or natural gas. The surface structure and polarity are dependent on the manufacturing process used. Thermal Black is made by decomposing natural gas in an atmosphere free of oxygen. Acetylene Carbon Black is made from the thermal decomposition of acetylene. The classes of Carbon Black pigments include: Channel, Furnace, Lamp, Thermal and Acetylene. Table 1 provides a comparison of carbon black pigment types.

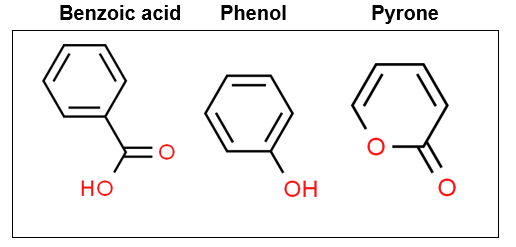

Carbon Black Structure – Carbon Blacks are normally comprised of elemental carbon arranged in 6-membered aromatic rings with available functional groups such as ketones, carboxyl, hydroxyl, quinone, and lactone. Their structure is similar to that of graphene, but graphene is more structured, being comprised of stacked amorphous and crystalline sheets which contribute to graphene’s conductivity.

Figure 2 – Typical functional moieties on carbon black

Due to Carbon Black’s surface structure, high polarity and porosity, they have a high oil absorption and vehicle demand. This in turn contributes to high viscosity and at times catalyst absorption. Lastly, many Carbon Black pigments have an acidic pH which can detract from corrosion resistance in some formulations. To improve the dispersion efficiency of Carbon Black, dispersing agents are commonly used.

Resources

UL Prospector® Knowledge Center and Search Engine

Wikipedia

Organic Coatings, Science and Technology, Third Edition, Wiley, Wicks e.al. 2007

Organic Coatings, Science and Technology, Fourth Edition, Wiley, Jones e.al. 2017

Research Gate

Chem Spider

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.