Pigments are crucial components in paints and coatings, providing color, opacity, and in some cases, functional properties such as corrosion resistance or UV protection. The choice of pigment and its method of incorporation can significantly impact the performance, durability, and aesthetic appeal of the final product. This article explores the various types of pigments used in the industry, focusing on organic and inorganic pigments, and discusses the best practices for incorporating them into paints and coatings.

Pigments are crucial components in paints and coatings, providing color, opacity, and in some cases, functional properties such as corrosion resistance or UV protection. The choice of pigment and its method of incorporation can significantly impact the performance, durability, and aesthetic appeal of the final product. This article explores the various types of pigments used in the industry, focusing on organic and inorganic pigments, and discusses the best practices for incorporating them into paints and coatings.

Types of Pigments

Inorganic Pigments

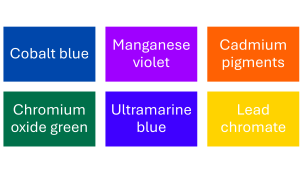

Inorganic pigments are typically derived from natural mineral sources or synthesized through chemical processes. They are known for their excellent opacity, durability, and resistance to weathering. Key inorganic pigments include:

- Titanium Dioxide (TiO₂)

Titanium dioxide (TiO₂) is one of the most widely used white pigments in the world. It is prized for its brightness, high refractive index, and UV resistance, making it a key component in a variety of applications, from paints and coatings to cosmetics and food products.

- Iron Oxides

Iron Oxides come in colors such as red, yellow, brown, and black. They possess good lightfastness, chemical resistance, and opacity. Commonly used in construction and industrial applications.

Other examples of inorganic pigments are:

Titanium dioxide

Titanium dioxide (TiO₂) is one of the most widely used white pigments in the world. It is prized for its brightness, high refractive index, and UV resistance, making it a key component in a variety of applications, from paints and coatings to cosmetics and food products.

In the United States, the Food and Drug Administration (FDA) regulates the use of titanium dioxide in various products. It is approved for use as a color additive in food, subject to certain restrictions on concentration. It is also approved for use in cosmetics and personal care products, including sunscreens, with specific regulations regarding particle size and concentration.

The regulatory status of titanium dioxide in the European Union has undergone significant changes in recent years.

- Food Additive: As of 2021, the European Food Safety Authority (EFSA) re-evaluated titanium dioxide (E171) and concluded that it could no longer be considered safe as a food additive. This led to a proposal by the European Commission to ban its use in food products, effective from August 2022.

- Cosmetics and Other Uses: In non-food applications, titanium dioxide remains widely used, but with increased scrutiny regarding its safety, particularly concerning its nanoparticle form.

Pigment extenders

Next to the inorganic pigments mainly used for their colorant properties, there is a separate class of inorganic pigments known as pigment extenders or fillers. Pigment extenders, also known as fillers, are materials added to paint and coating formulations to improve their properties, reduce costs, and enhance performance without significantly affecting the color. They play a crucial role in modifying the physical and chemical characteristics of the final product.

The most used pigment extenders in paint formulation are:

- Calcium Carbonate (CaCO₃): Provides brightness and opacity, and improves durability and gloss.

- Kaolin (Hydrated Aluminum Silicate): Offers good anti-settling properties and improves the rheology of the paint. Used for its opacity and smooth finish.

- Talc (Hydrated Magnesium Silicate): Enhances the paint’s smoothness, acts as a matting agent, and improves anti-corrosion properties. It also contributes to good spreading and leveling characteristics.

- Silica (SiO₂): Improves the durability and mechanical properties of the coating, increases hardness, and reduces gloss for a matte finish.

- Barites (Barium Sulfate, BaSO₄): Provides high density, good chemical resistance, and increases the weight of the paint. It is used in industrial coatings for its inertness and high specific gravity.

- Mica: Enhances the barrier properties of the coating, providing improved moisture resistance and flexibility. It is used in anti-corrosive and protective coatings.

- Zinc oxide (ZnO): Good UV resistance and opacity. It also has antibacterial properties.

Organic Pigments

Organic pigments are based on carbon chains and rings and are generally derived from petrochemical processes. They offer a wider range of bright, vivid colors compared to inorganic pigments but often have lower opacity and stability.

- Phthalocyanine Pigments

- Azo Pigments

- Quinacridone Pigments

- Dioxazine Pigments

- Perylene Pigments

- Anthraquinone Pigments

Carbon black

While carbon black is technically an organic pigment due to its carbon composition, derived from organic sources such as natural gas or oil, it is often treated as a separate category because of its distinct characteristics and wide range of industrial applications. Its production methods, properties, and uses set it apart from traditional organic pigments, making it a unique and valuable material in many fields.

A more environmentally friendly alternative is recovered carbon black (rCB), rCB is produced by pyrolyzing end-of-life rubber products, primarily tires. Pyrolysis involves heating the rubber in the absence of oxygen, causing it to decompose thermally. Virgin CB generally has higher purity with fewer contaminants. rCB may contain trace amounts of ash and other residues from the pyrolyzed rubber. Also, CB typically has a more uniform particle size and structure, while rCB’s properties can vary based on the pyrolysis process and feedstock composition.

More info: /17258/pc-more-than-meets-the-eye-carbon-black-pigment/

Natural pigments

Natural pigments are derived from plant, animal, or mineral sources. They are less commonly used in industrial applications but remain important in specific niches.

Examples of natural pigments are:

- Ochres: origin from iron oxide minerals

- Indigo: plant-based source (Indigofera species)

- Carmine: cochineal insects, bright in color but not very lightfast

Special effect pigments

Special effect pigments are designed to create unique visual effects in coatings and other applications. They include metallic, pearlescent, and fluorescent pigments.

- Metallic Pigments: from aluminum, copper, and zinc used for their metallic sheen and reflectivity

- Pearlescent Pigments: mica coated with titanium dioxide or other oxides

- Fluorescent Pigments: bright, glowing colors under UV light

- Photochromic Pigments: change color in response to light exposure. Used in novelty items, security inks, and specialty coatings

Best Practices for Incorporating Pigments into Paints and Coatings

Dispersion Techniques

The effectiveness of a pigment in a paint or coating depends heavily on how well it is dispersed within the binder matrix. Poor dispersion can lead to issues such as flocculation, reduced color strength, and poor film properties. Key dispersion techniques include:

- High-Speed Dispersers: Suitable for low to medium-viscosity systems.

- Ball Mills: Ideal for achieving fine dispersion.

- Bead Mills: Effective for high-viscosity systems and difficult-to-disperse pigments

- Three-roll Mills: Used for highly viscous pastes. Pigments are dispersed by shear forces between rotating rollers

Wetting and Dispersing Agents

Additives play a critical role in enhancing pigment dispersion. Wetting agents reduce the surface tension of the binder, allowing better pigment wetting. Dispersing agents stabilize the dispersed pigment particles and prevent re-agglomeration. Commonly used agents include:

- Anionic Surfactants: Provide good wetting properties but may impact water resistance.

- Nonionic Surfactants: Offer balanced wetting and compatibility with various systems.

- Polymeric Dispersants: Provide excellent stabilization and are particularly useful for difficult-to-disperse pigments.

More information can be found on the Prospector® Knowledge Center about the dispersing of pigments: The Basics of Dispersion and Stabilization of Pigments and Fillers

Conclusion

Pigments are a vital component of paints and coatings, influencing not just color but also performance and durability. Understanding the properties of different pigments and the best practices for their incorporation is crucial for formulating high-quality coatings. By leveraging appropriate dispersion techniques and additives, manufacturers can optimize pigment performance to meet the specific requirements of their applications.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.