In September 2021 and again in November 2022, I contributed articles on medical plastics. This new article is a further roundup of new developments in this fast-moving field. They range from the mundane to the exotic and innovation by medical device producers continues to accelerate. Plastic materials have a unique and important role to play in the medical field and with appropriate material selection, will continue to be used for the next generation of medical devices.

Polymorphic moulding for zero tooling waste and high speed

Fyous is launching the world’s first, infinitely reusable moulding technology; polyMorphic moulding, launched in June at the RAPID + TCT event in Los Angeles, can shapeshift in under 20 minutes, producing zero tooling waste and making usable parts 14 times faster than 3D printing.

Initially targeted at creating bespoke footwear for athletes, because this proprietary manufacturing process allows for the rapid and accurate production of custom products, Fyous has expanded its application to include medical applications.

Co-founders Joshua Shires and Thomas Bloomfield expect polymorphic moulding to disrupt the manufacturing sector, by enabling products to be brought to market that were previously not commercially viable or enable products to be bought to market much faster. The technique features more than 28,000 densely packed pins to create the mould. Once the pins are in position, the mould can withstand six tonnes of distributed pressure.

By inputting a 3D CAD model, Fyous software generates the PolyMorphic mould shape. The PolyMorphic machine then shapeshifts the mould to create the intended product. On completion of production, the PolyMorphic mould is returned to the machine, ready for the next shapeshift.

By inputting a 3D CAD model, Fyous software generates the PolyMorphic mould shape. The PolyMorphic machine then shapeshifts the mould to create the intended product. On completion of production, the PolyMorphic mould is returned to the machine, ready for the next shapeshift.

Laser welding targets medical market

Emerson has announced the Branson GLX-1 laser welder, which offers users flexibility to meet the growing demand for joining small, complex or delicate plastic components and assemblies. Its small footprint and modular design make it compatible for use in ISO-8 cleanroom environments, while an integral automation controller simplifies installation and interfaces with production robotics.

Servo-based actuation controls allow for greater freedom to design and join components with three-dimensional contours in small-part applications for the medical market, such as catheters and wearables with microfluidic parts, as well as sensors in the electronics, automotive and appliance markets.

Kintaro-ame for microscale spiral devices

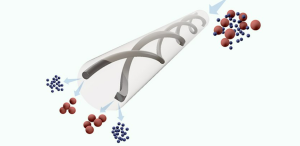

Researchers from Tohoku University and Okinawa Institute of Science and Technology (OIST) have advanced microfluidics, for precise and efficient manipulation of fluids in three-dimensional microscale environments. This work opens up new possibilities for bioanalytical applications, such as cell separations in medical diagnostics.

Microfluidic devices are designed to handle minuscule fluid volumes, allowing researchers to perform analyses and processes with remarkable precision and efficiency. Their intricate corkscrew-like design allows for precise fluid control, efficient particle separation, and reagent mixing. However, their potential to revolutionize bioanalytical applications is currently hindered by fabrication challenges. The process is time-consuming and costly, and existing manufacturing techniques limit material options and structural configurations.

To overcome these limitations, the Tohuku team has introduced a miniaturized rotational thermal drawing process (mini-rTDP), drawing inspiration from traditional Japanese candy-making techniques – the fabrication of Kintaro-ame.

Their innovative approach involves rotating the materials during thermal stretching to create intricate three-dimensional structures within fibres. This process is highly versatile, accommodating a wide range of materials that can deform when heated, unlocking endless possibilities for combining diverse materials.

“Mini-rTDP involves creating a moulded polymer preform containing channels, which are subsequently stretched and heated to generate microfluidic channels within a fibre,” explained a spokesman for the team. “These channels can then be further rotated to shape three-dimensional spiral configurations. The rapid prototyping of three-dimensional spiral microfluidics using mini-rTDP offers unparalleled versatility, precision, and the potential to catalyse transformative changes across various industries. Furthermore, we are actively pursuing the integration directly into fibres of electrodes, biosensors, and actuators. This could revolutionize Lab-on-Chip bioanalytical technologies.”

Discover Prospector Premium, learn more here!

Innovative 3D printing for cataracts

University of East Anglia researchers have made a significant breakthrough with the introduction of a novel resin for 3D printing intraocular devices. It could enhance the manufacture of eye implants universally used in cataract and refractive surgeries.

An artificial intraocular lens (IOL) is primarily required for people with cataracts, a condition where the eye’s natural lens becomes cloudy, obscuring vision. They can also be also used to correct refractive errors such as myopia (near-sightedness), hyperopia (farsightedness) and presbyopia (when eyes gradually lose the ability to see things clearly up close, as a normal part of aging).

“For the first time, we have developed a resin that can be used to print ocular devices directly,” said Dr. Aram Saeed, Associate Professor in Healthcare Technologies at UEA’s School of Pharmacy. “While still in the early stages, the ability to 3D print these lenses could significantly enhance eye care for patients by offering unprecedented levels of customization and design precision, potentially leading to better clinical outcomes.”

Historically, IOLs have been made from a variety of materials, including glass and silicone, although more recently the industry has significantly evolved to predominantly use acrylic materials.

Currently hydrophilic and hydrophobic acrylic are the most commonly used materials, due to their excellent optical clarity, flexibility, biocompatibility with the body and for their stability and safety within the eye.

Current methods of making IOLs use lathing and moulding techniques. While these methods offer the production of well-engineered and high-optical quality devices, they also come with inherent limitations, particularly in terms of design complexity and customization.

“3D printing could significantly enhance the production of ocular devices, not only improving speed and precision in manufacturing but also enabling greater complexity and customization in design,” added Dr. Saeed.

3D-printed phantom brain trains analytical software

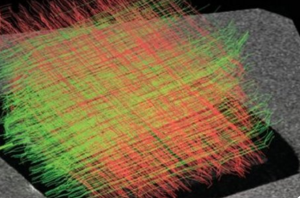

In a joint project between MedUni Vienna and TU Wien, the world’s first 3D-printed “brain phantom” has been developed, which is modelled on the structure of brain fibres and can be imaged using a special variant of magnetic resonance imaging (dMRI). These brain models can be used to advance research into neurodegenerative diseases such as Alzheimer’s, Parkinson’s and multiple sclerosis.

Magnetic resonance imaging (MRI) is a widely used diagnostic imaging technique that is primarily used to examine the brain. MRI can be used to examine the structure and function of the brain without the use of ionising radiation. In a special variant of MRI, diffusion-weighted MRI (dMRI), the direction of the nerve fibres in the brain can also be determined. However, it is very difficult to correctly determine the direction of nerve fibres at the crossing points of nerve fibre bundles, as nerve fibres with different directions overlap there. In order to further improve the process and test analysis and evaluation methods, the team has developed a so-called “brain phantom”, produced using a high-resolution 3D printing process. This authentic reproduction of characteristic nerve structures in the brain is important for “training” the dMRI analysis software.

Back in 2017, a two-photon polymerisation printer was developed at TU Wien that enables upscaled printing. In the course of this, work was also carried out on brain phantoms as a use case together with the Medical University of Vienna and the University of Zurich. The resulting patent forms the basis for the brain phantom that has now been developed and is being supervised by TU Wien’s Research and Transfer Support team.

Visually, this phantom is much smaller than a real brain and has the shape of a cube. Inside it are extremely fine, water-filled microchannels the size of individual cranial nerves. The diameters of these channels are five times thinner than a human hair. In order to imitate the fine network of nerve cells in the brain, the research team used two-photon polymerisation, which is primarily used to print microstructures in the nanometre and micrometre range – not for printing three-dimensional structures in the cubic millimetre range. In order to create phantoms of a suitable size for dMRI, the researchers at TU Wien have been working on scaling up the 3D printing process and enabling the printing of larger objects with high-resolution details.

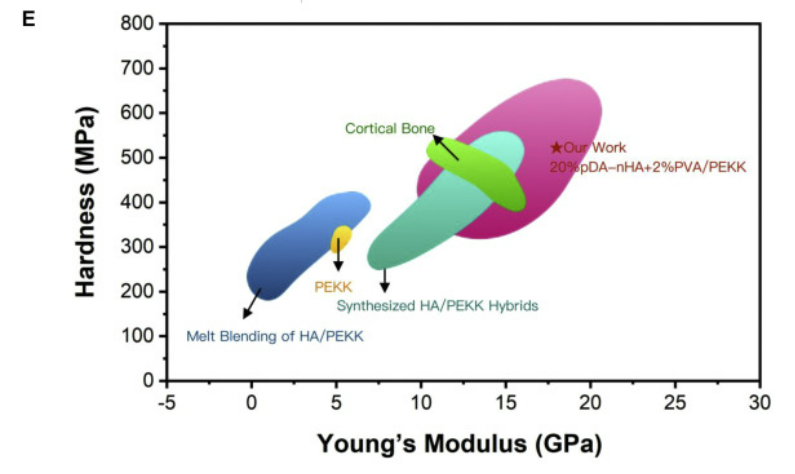

PEKK-reinforced composites for bone tissue engineering

Nano hydroxyapatite (nHA), the primary inorganic component of bone widely utilized in bone tissue engineering, suffers from poor mechanical properties when used alone. Conversely, polyetherketoneketone (PEKK), a high-performance polymer approved by the US Food and Drug Administration (FDA) and used in dentistry and biomaterial science, struggles with bio-inertia – preventing any irritation or sensitive reactions with the body – affecting its use in osteogenesis – the process of bone formation.

Now, researchers from Sichuan University, China, have introduced pDA-nHA/PEKK composites that combine high strength and bioactivity.

“The optimal combination of nHA and PEKK can achieve higher mechanical property and bioactivity,” says Zhongyi Wang. “Nevertheless, conventional melt blending techniques often result in weakened strength due to nanoparticle agglomeration and the lack of chemical bonds between the inorganic and organic constituents.”

To that end, the team studied the structure of cortical bone. By employing freeze-casting, the researchers mimicked the bone’s hierarchical structure, known for its exceptional stiffness and toughness. The resulted in pDA-nHA scaffolds with enhanced osteo-inductive abilities and supplemented mechanical strength through PEKK.

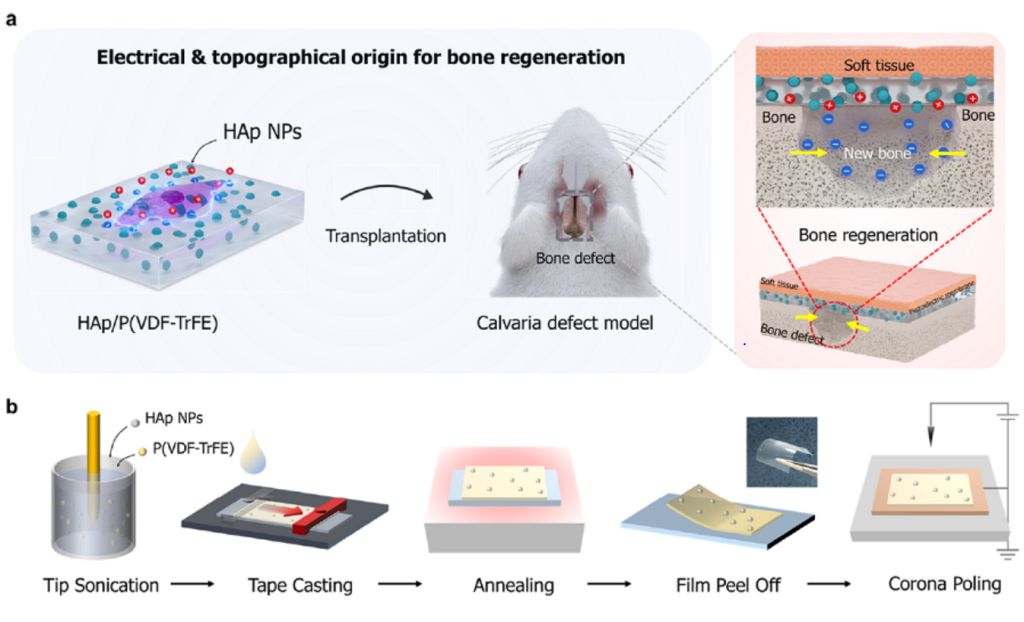

Piezoelectric “bandage” helps regenerate cracked bones

Bone regeneration is a complex process, while existing methods to aid regeneration face limitations, not least high cost. Now, a piezoelectric material that can promote the growth of bone tissue has been developed in South Korea by a team from KAIST.

By utilizing the unique osteogenic ability of hydroxyapatite (HAp), the development comprises a biomimetic scaffold that generates electrical signals upon the application of pressure. HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research explores a method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

“We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration,” commented Professor Hong from KAIST’s Department of Materials Science and Engineering (DMSE). “This research not only suggests a new direction for designing biomaterials but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

Caption: Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process.

Arise kirigami hydrogels

Hydrogels are a class of finely structured soft, flexible and expandable materials. They have a network of water-attracting (hydrophilic) molecules, allowing their structure to swell substantially when exposed to water that becomes incorporated within the molecular network.

Hydrogels are being explored for medical applications, including tissue engineering, wound dressings, drug delivery systems and materials that can adapt flexibly to movement and growth.

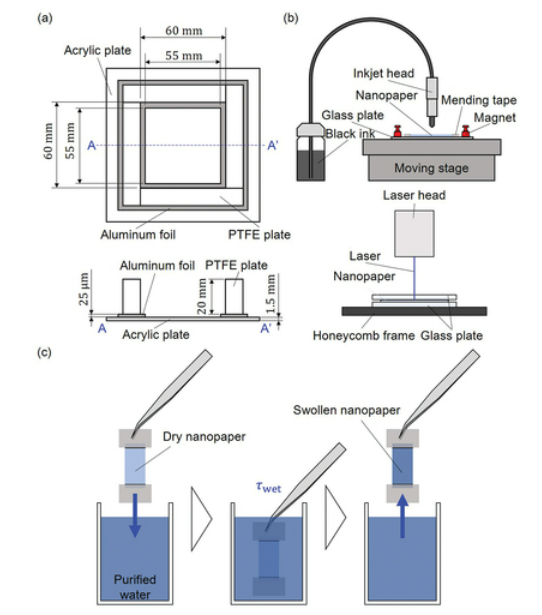

Work being undertaken at the Tokyo University of Agriculture and Technology (TUAT), extends the emerging field of ‘kirigami hydrogels’, in which patterns are cut into a thin film, allowing it to later swell into complex hydrogel structures. Kirigami literally means the cut design of papers, it was originally intended for thin sheet structures. Researchers have worked with an initially dry film composed of nanofibres of cellulose, the natural material that forms much of the structure of plant cell walls.

Laser processing was used to cut structures into film, before water was added allowing the film to swell. The Kirigami pattern allows the width to increase when stretched in the longitudinal direction (called the auxetic property), which is possible if the thickness grows sufficiently when the original thin film is wetted.

“Our two-dimensional auxetic mechanism manifests when the thickness of the sheet is sufficient, and the three dimensionality of the hydrogel structure emerges by swelling when it is used,” explained researcher Itsuo Hanasaki. “It is convenient to store it in the dry state before use, rather than keeping the same water content level of the hydrogel. Furthermore, the auxetic characteristic is maintained during the cyclic loading that causes the adaptive deformation of the hydrogel to reach another structural state. This is important for the design of intelligent materials.”

Caption: Schematic diagrams for sample fabrication: (a) container to dry aqueous CNF dispersion for nanopaper fabrication; (b) inkjet drawing and laser processing for specimen preparation including kirigami structures; (c) dipping nanopaper specimen to fabricate CNF hydrogel for a certain wetting time.

Sunlight for medical therapies and desalinating seawater

Researchers from the UPC’s research group Innovation in Materials and Molecular Engineering – Biomaterials for Regenerative Therapies (IMEM-BRT) are working on a thermosensitive hydrogel with several applications, such as the creation of new biomedical adhesives for semi-invasive therapies and for medical diagnosis, and the desalination of seawater with solar radiation.

The TherGel project focuses on developing a thermosensitive conductive hydrogel called solar absorber hydrogel (SAH). Thermosensitive hydrogels are polymeric materials capable of absorbing a large amount of water, depending on the temperature to which they are exposed, and expelling it free of salts and contaminants when heated above 32ºC. A conductive polymer is added, which acts as a photothermal absorber and enhances the water expulsion capacity, that is, the generation of potable water.

The property of thermosensitive hydrogels to retain liquids and respond to temperature changes makes them suitable for their application in medical implants, such as surgical meshes for repairing abdominal hernias, sponges for draining fistulas after surgical procedures and dressings for wounds, to name a few.

The presence of the hydrogel in surgical meshes, for example, facilitates their adaptation to tissues due to the material’s adhesion capacity and the possibility of detecting the implant through surface-enhanced Raman spectroscopy (SERS). IMEM-BRT researcher Sonia Lanzalaco explains, “During implantation, the hydrogel is capable of self-opening to adapt to human body temperature, and once implanted it can provide information on temperature changes caused by a potential localised infection. Thanks to this hydrogel, the mesh could better adapt to organs, both in terms of flexibility and biocompatibility.”

The hydrogel could be manufactured at home with a preparation kit, since no industrial equipment is required, and it could be reused or recycled at home too.

Caption: Hydrogel samples. The black colour indicates the utilisation of conductor polymer nanoparticles

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.