Plastics aren’t going anywhere and have much to offer to provide a sustainable future. So, is it time to work with plastic manufacturers instead of confronting them with bans? What does the immediate future hold for the plastic sector? Andy Pye looks at some examples of positive contributions being made by the polymer industry.

From the development of biodegradable and sustainable plastics to the integration of smart technologies, the sector is adapting to address pressing environmental concerns and societal needs. According to Michael Laurier, CEO of Symphony Environmental, these are the five key trends to look for in the plastics sector in 2025:

The Circular Economy: Central to this are minimising waste and promoting the recycling and reuse of plastics. Companies are now designing products with recycling in mind, opting for materials that can be efficiently processed through recycling systems or biodegrade.

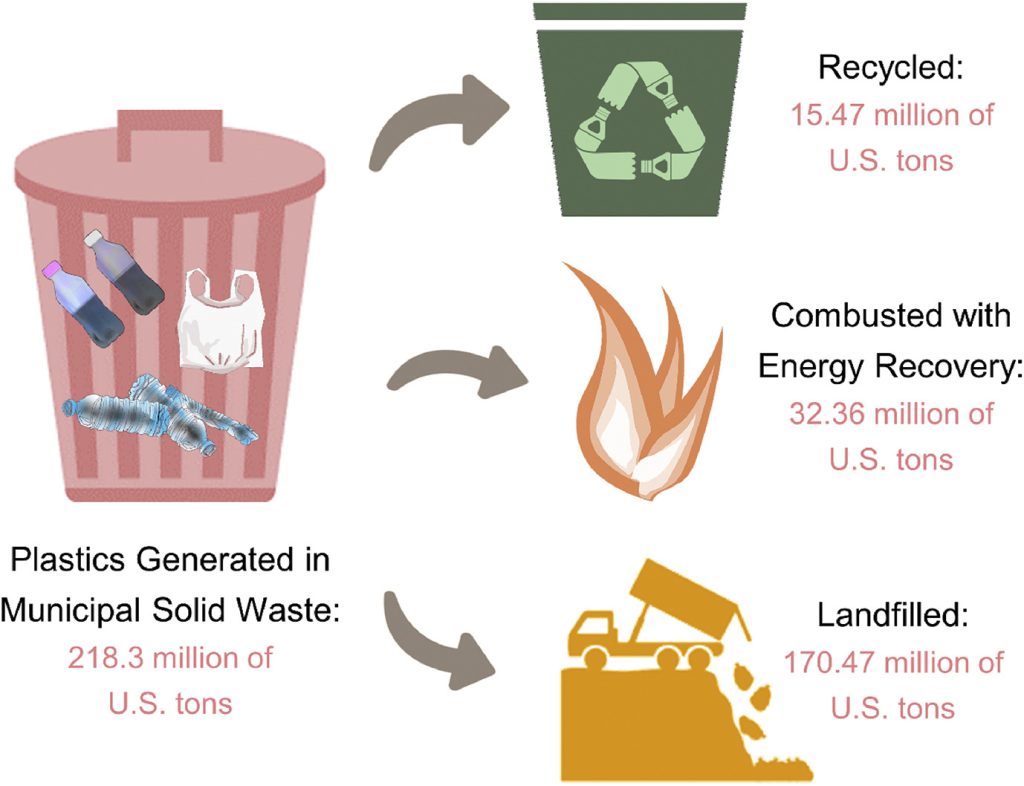

The fate of plastics generated in municipal solid waste in the United States from 1960 to 2017 (Ref 3).

Biodegradable plastics: Biodegradable plastics are becoming central to the ongoing efforts to mitigate the environmental impact of traditional plastic materials. Ordinary polyethylene and polypropylene products can be made to biodegrade much more quickly if they get into the environment, leaving no microplastics behind.

Regulatory framework: Many governments and international organisations are driving major change in the regulatory landscape to strengthen and enforce responsible plastic management. A central part of this has been the increase in restrictions on single-use plastics, though restrictions on plastic can steer people toward less sustainable materials such as paper.

Smart Plastics: these can protect people against insects, rodents and fire, and can reduce the deterioration of food.

Anti-Microbial Plastics: these have emerged as a significant and timely trend. As a direct result of the heightened emphasis on hygiene, particularly within healthcare environments, this innovative approach involves the integration of substances with inherent anti-microbial or anti-viral qualities into the plastic manufacturing process.

Discover Prospector Premium, learn more here!

Construction polymers

FactMR recently launched a report on the construction polymers market, which is characterized by a diverse array of global and regional players. The increasing demand for reliable raw materials in the construction sector is expected to drive the growth of the construction polymers market globally. Notably, the building and construction segment constitutes a significant portion, approximately 20%, of the global construction polymers market, followed closely by the automotive industry.

Construction polymers find extensive applications in various sectors, including amongst others road construction, roofing, foundations, panelling, glazing sealants, bridge bearings, waterproof membranes and flooring.

Despite growing demand, construction polymers face challenges related to performance assessment, longevity, and environmental sustainability. However, initiatives by governments to promote environmentally sustainable construction materials and regulations aimed at reducing carbon emissions are creating favourable conditions for the growth of the construction polymers market.

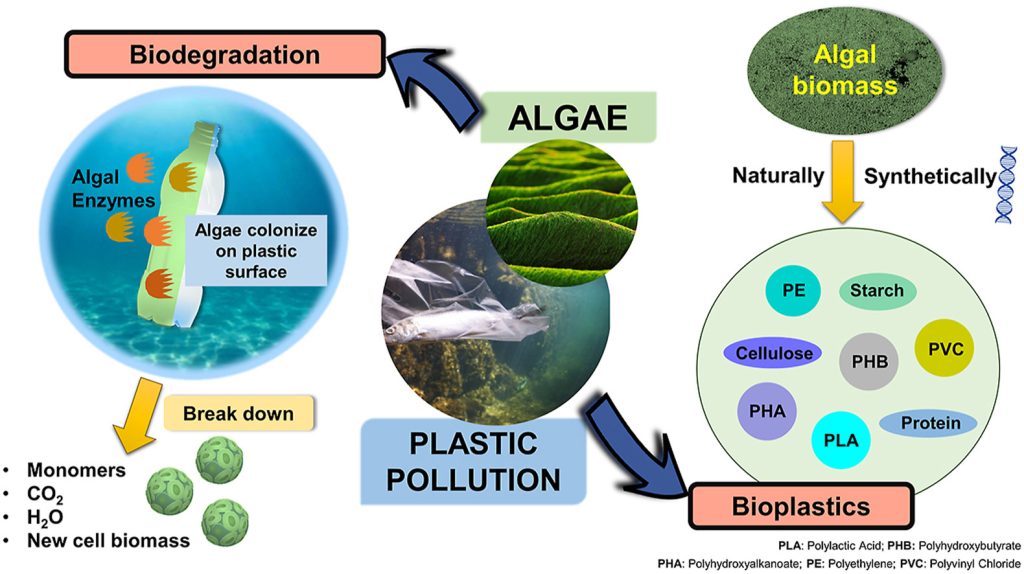

Biodegradable plastic from algae

Until now, the development of plastics has been almost exclusively based on fossil fuels. Over the past 50 years, annual global production has increased from 1.5 million tonnes to over 395 million tonnes. Essentially, most fossil-based plastics end up in landfills – only about 9% is recycled and 12% incinerated, while the remaining 79 percent will slowly decompose, taking hundreds of years.

The algal strain Coelastrum astroideum (RW-10) producing carbohydrates in control media and synthetic wastewater

Now, the Waste2Plastic project at Umeå University in Sweden has received SEK 15 million from the Swedish Energy Agency and its industrial partners to produce PHA biodegradable plastics using microalgae.

At the Dåva waste treatment plant in Umeå, microalgae are grown in wastewater, both in greenhouses and outdoors

The Waste2Plastic project aims to reduce the carbon footprint by using local strains of Nordic microalgae as raw materials, reducing the consumption of fossil fuels in the production of bioplastics and making the plastics biodegradable.

Algae for plastic biodegradation and bioplastics production

“Bio-based plastics, generated from renewable resources, can play an important role in the circular economy to avoid the use of fossil fuels, but while biodegradable plastics have been proposed as a substitute to meet future plastic needs, in 2022, they accounted for only 1% of the plastic produced in the world,” says Christiane Funk, project manager at the Department of Chemistry. “One of the biggest problems is relatively high production costs. Here, the biomass will be fed to bacteria that create plastic for lamps and packaging. We are on our way to a sustainable bioplastics industry. The project also involves new methods for degradation or recycling and fewer toxic chemicals in the manufacturing stages.”

Vaporizing plastic bags and bottles

In recycling, the higher up the “food chain” the recycled materials can be adopted, the greater the potential. In one Californian project, a new chemical process is being developed that can vaporize the plastics that dominate the waste stream today and turn them into hydrocarbon building blocks for new plastics. This catalytic process, discovered by researchers at Berkeley Lab and UC Berkeley, reduces polymers to chemical precursors, bringing a circular economy for plastics one step closer.

The process works well with the, the two dominant types of post-consumer plastic waste: polyethylene, a component of most single-use plastic bags; and polypropylene, the stuff of hard commodity plastics used in applications like microwavable dishes to luggage.

If scaled up. the project could help bring about a circular economy for many “throwaway plastics”, with the plastic waste converted back into the monomers originally used to make the polymers, thereby reducing the fossil fuels used to make new plastics. Clear plastic water bottles made of polyethylene terephthalate (PET), a polyester, were designed in the 1980s to be recycled this way. But the volume of polyester plastics is minuscule compared to that of the polyolefins.

“We have an enormous amount of polyethylene and polypropylene in everyday objects, from -lunch bags to laundry soap bottles to milk jugs – so much of what’s around us is made of these polyolefins,” said John Hartwig, a senior faculty scientist in Berkeley Lab’s Chemical Sciences Division. “What we can now do, in principle, is take those objects and bring them back to the starting monomer by chemical reactions that we have devised. These cleave the typically stable carbon-carbon bonds. By doing so, we’ve come closer than anyone to give the same kind of circularity to polyethylene and polypropylene that you have for polyesters in water bottles.”

Reference: https://newscenter.lbl.gov/2024/08/29/new-process-vaporizes-plastic-bags-and-bottles-yielding-gases-to-make-new-recycled-plastics/

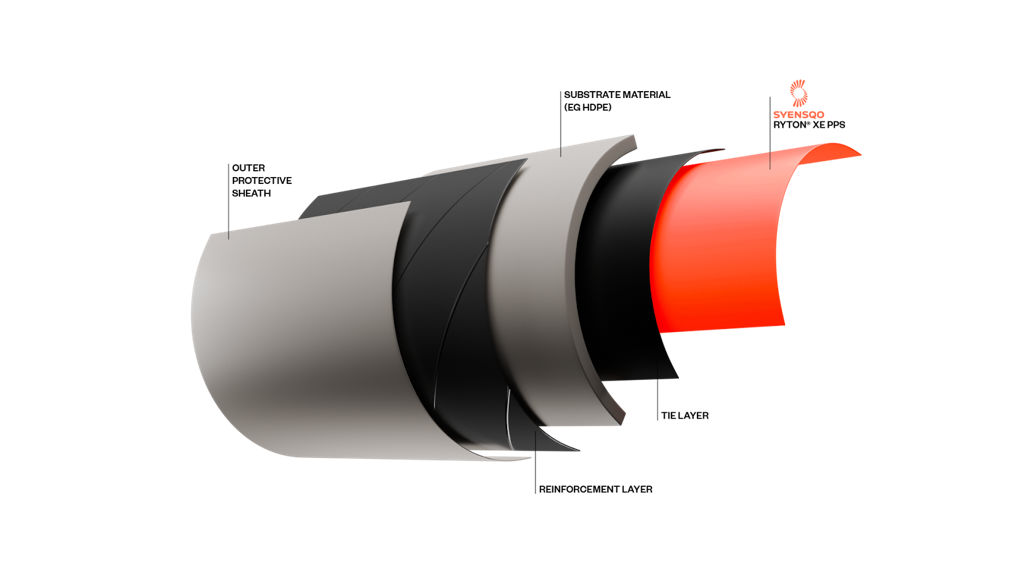

Extrudable PPS for sustainable piping

has launched Ryton PPS XE-5000NA, the first grade of an innovative extrudable polyphenylene sulfide (PPS) technology, set to improve the performance and sustainability of piping materials.

Ryton PPS XE-5000 offers superior chemical and permeation resistance in challenging environments

“There is a growing need for new piping materials capable of exceeding the chemical, thermal and pressure resistance of conventional polyethylene or polyamide resins,” said William Sattich, Principal Scientist for PPS at Syensqo. “In addition to meeting these requirements, advanced Ryton PPS XE-5000 technology delivers high-performance extrudable thermoplastic compounds with a permeation resistance far superior to that of the common piping materials used in the energy industry.”

Ryton PPS XE-5000 is targeted at pipes operating in high-temperature and high-pressure environments. Its exceptional chemical and permeation resistance make it an economical and efficient choice for both traditional and emerging energy applications. With excellent extrusion properties, XE-5000NA is ideal for use in inner liners, stand-alone and composite pipes.

References

1 Microalgae from Umeå can be used to produce bioplastic

https://www.umu.se/en/news/microalgae-from-umea-can-be-used-to-produce-bioplastic_11905774/

2 New Process Vaporizes Plastic Bags and Bottles, Yielding Gases to Make New, Recycled Plastics

3 Plastics: material-specific data

https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.