A polymer’s properties are grounded in its’ monomer composition. An optimized monomer composition brings multiple desirable properties to the polymer made from it. These could include, increased hardness, improved weathering resistance, and crack resistance. Coatings formulators cannot usually control monomer composition of the polymers we utilize. Nevertheless, knowing the properties specific building blocks bring to the table is important. Isobornyl Methacrylate (IBOMA) is a specialty monomer which imparts several desirable properties to polymers used to formulate a variety of coatings types. Let’s explore IBOMA’s structure, what polymer properties it can yield, and how it can affect important aspects of a coating formulation. Some of those affected properties include dry film performance, weatherability, and sustainability.

A polymer’s properties are grounded in its’ monomer composition. An optimized monomer composition brings multiple desirable properties to the polymer made from it. These could include, increased hardness, improved weathering resistance, and crack resistance. Coatings formulators cannot usually control monomer composition of the polymers we utilize. Nevertheless, knowing the properties specific building blocks bring to the table is important. Isobornyl Methacrylate (IBOMA) is a specialty monomer which imparts several desirable properties to polymers used to formulate a variety of coatings types. Let’s explore IBOMA’s structure, what polymer properties it can yield, and how it can affect important aspects of a coating formulation. Some of those affected properties include dry film performance, weatherability, and sustainability.

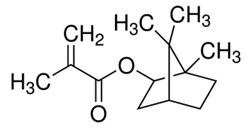

Structure of IBOMA

Isobornyl Methacrylate (molecular mass 222.32 grams per mole) combines a complex, aliphatic polycyclic structure with methacrylate functionality. The IUPAC naming convention for IBOMA is [(1R,4R)-4,7,7-trimethyl-3 bicyclo[2.2.1]heptanyl] 2-methylprop-2-enoate. Many of the unique properties IBOMA imparts to polymers made with it are the result of large polycyclic aliphatic side chains. The majority of polymers utilizing IBOMA are synthesized by radical initiated chain polymerization reactions of the methacrylate group. Through co-polymerization with a wide variety of acrylate and methacrylate functional monomers, IBOMA containing polymers suitable for countless coatings applications are produced.

Polymer Properties Derived from IBOMA

When incorporated into a co-polymer with compatible monomers IBOMA can provide many property improvements to coatings formulations. Increased hardness and higher glass transition temperatures are two related properties of IBOMA co-polymers. The homopolymer of IBOMA has a very high glass transition temperature at 110.5° C which is harder than the homopolymers of methyl methacrylate or Styrene. These are both commonly used to increase the glass transition temperature of a homopolymer. Since the Tg of a co-polymer is the weighted average of the homopolymer glass transition temperatures of its constituent monomers, the addition of small amounts of IBOMA can have a disproportionate effect on the Tg. Unlike hard polymers made with methyl methacrylate or styrene, those using IBOMA are not brittle. This enhances the flexibility of the coating and makes it more flexible with increased resistance to cracking and crazing.

The increased flexibility of IBOMA containing polymers also enhances the adhesion of the coatings formulated from them. This effect is due to stronger interactions between coating and substrate made possible by the better wetting of the surface. The bulky isobornyl group increases intermolecular attraction between the coating and surface by amplifying the influence of Van der Waals forces. This adhesion improvement is shown over various substrates including metals, wood and plastics. Improved adhesion may eliminate the need for primers and increase the performance of a coating in other areas such as corrosion and moisture resistance.

Solvent based coatings polymers containing IBOMA typically have lower viscosity than those made from other monomers at equal solids levels. This enables lower VOC paint formulations since higher nonvolatile content can be achieved at the same application viscosity. Higher solids coatings have many advantages including lower pollution from evaporating solvents, a cleaner and safer working environment for the painters, and higher dry film thickness per coat during application. These low VOC coatings also have better durability because IBOMA increases a polymer’s resistance to breakdown by UV radiation in exterior uses. IBOMA containing polymers can be very effective to formulate direct to metal (DTM) coatings both as solvent borne or waterborne systems.

Gain the ingredient insights you need with Prospector Premium. Learn more here!

Waterborne Coatings

IBOMA readily polymerizes with other acrylic and methacrylic functional monomers under the conditions commonly used to manufacture latex polymers. In these polymers it brings to the table the same performance enhancements it does in solvent borne coatings. The hardness, scratch and mar resistance, and weatherability of the waterborne coatings are enhanced. Improved adhesion to a variety of substrates, and increased flexibility also result from the incorporation of IBOMA. This improved flexibility and adhesion can, for example give an exterior architectural coating better resistance to cracking and chipping.

UV Cure Coatings

IBOMA is very important as an ingredient in UV cured coatings, it is especially useful to achieve hardness and scratch resistance in the cured film. Excellent photo-stability is another property IBOMA can add to UV cured polymer coatings. This suite of properties can be especially important in common UV cure applications like hard-coats for automotive headlight lenses. Oligomers containing IBOMA have lower inherit viscosity than comparable molecular weight versions made with other monomer compositions. Monomeric IBOMA can be used as a fast reacting diluent to lower the viscosity of UV curable polymer and oligomer solutions which facilitates easier handling and better application of the formulated coating. In the next section we will explore how IBOMA can increase the sustainability of UV cured coatings beyond the current environmental advantages they currently hold

Sustainability

IBOMA is readily manufactured from renewable non food chain resources such as camphor or pinene and the biobased content can be as high as seventy one percent. Biobased versions of IBOMA, for example Visiomer® Terra IBOMA from Evonik are commercially available. This makes them a more sustainable alternative to other hard monomers such as methyl methacrylate and styrene made from petroleum feedstocks. Using plant based, renewable raw materials is an effective way to lower the Product Carbon Footprint (PCF) of your formulation. The decreased PCF of any renewable based raw materials in your formulation are subtracted after calculating total Scope 3 carbon emissions.

Additionally, the ability to make higher solids, lower VOC solvent borne coatings and IBOMA’s performance enhancing properties in both high solids solvent borne coatings and waterborne coatings makes IBOMA containing polymers an all-around sustainable choice for your coatings formulations. If you combine the use of renewable resource derived IBOMA with these other advantages, you can significantly lower the PCF of your coating. These are passed on to your customer as reductions in the Scope 3 emission of their finished product. UV cured coatings are at a particular advantage since they already have lower Product Carbon Footprints due to their low to no VOC contents and reduced energy demand during curing.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.