Various takes on the “Zombie Apocalypse” make for very popular science fiction scenarios. Many root causes of the resulting global disasters are explored including viruses, secret military experiments gone awry and even cosmic rays. At least two sci fi franchises place the blame on organisms not often thought of as catalysts for the end of civilization, Fungi. Both “The Last of Us” and “The Girl with All the Gifts” envision a post-apocalyptic world where mutated Cordyceps fungi infect humans, turning them into rampaging, flesh-eating undead creatures. Luckily, the fungi that affect coatings are not that destructive in comparison.

Various takes on the “Zombie Apocalypse” make for very popular science fiction scenarios. Many root causes of the resulting global disasters are explored including viruses, secret military experiments gone awry and even cosmic rays. At least two sci fi franchises place the blame on organisms not often thought of as catalysts for the end of civilization, Fungi. Both “The Last of Us” and “The Girl with All the Gifts” envision a post-apocalyptic world where mutated Cordyceps fungi infect humans, turning them into rampaging, flesh-eating undead creatures. Luckily, the fungi that affect coatings are not that destructive in comparison.

Fungi attack coatings in less dramatic ways than the renegade Cordyceps of fiction and video games. Degradation of coatings from fungal contamination can occur both in the can and on the applied dry film. Preventing the damage inflicted by fungi is important to maintain customer expectations of product quality and durability. There is a wide range of anti-fungal agents approved by various regulatory agencies for use in paints and coatings. Mold and mildew are the most common fungal contaminates of paints. Algae can also damage dry paint films in use. It is fortunate for the coatings formulator that many dry film fungicides also exhibit anti-algal activity.

Fungi were once classified in the Plant Kingdom, but now have their own Kingdom. Yeasts, molds, mildews, and mushrooms are commonly encountered members of Kingdom Fungi. In some ways they are actually biologically closer to animals than plants. A key difference between fungi and plants is the fact that fungi, like animals, are heterotrophs and absorb their food as dissolved molecules. Fungi typically excrete digestive enzymes into their environment to create these soluble molecules. A 2017 estimate placed the number of fungus species at 2.2 to 3.8 million. Fungi occur in many forms and have evolved into symbiotic and parasitic organisms as well as free-living life forms.

Fungicides

Fungicides are a subclass of biocides used to control fungal contamination in paints and other products. Depending on the nature of the fungicide it may act in the container, on the painted surface or both. This article will give a basic run down of the chemical classes of fungicides, what types of organisms they protect against, and whether they act as in-can or dry film preservatives. Classes of fungicides that also protect against algae will be noted. Secondly, it will outline techniques to optimize your fungicide package depending on your preservation needs and regulations applicable to the use of fungicides in paints.

Chemical Families of Fungicides

There are six major groupings of fungicides based on chemical structure. Let’s review each, outlining the types of organisms it protects against contamination from and whether it acts in-can, as a dry-film preservative, or both.

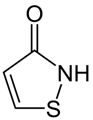

A. Isothiazolinones (the basic building block structure of the class is shown below)

are one of the most widely used and versatile classes of fungicides since they are active against bacteria and algae as well as fungi. There are many commercial isothiazolinone compounds used in coatings, often in combination with others in the class or other preservatives. Commercial Isothiazolinone based fungicides include:

- MIT Methylisothiazolinone

- CMIT Chloromethylthiazolinone

- BIT Benzisothiazolinone

- OIT Octylisothiazolinone

- DCOIT Dichlorooctylisothiazolinone

- BBIT Butylbenzisothiazolinone

Commercial pre-blended combinations of Isothiazolinone fungicides are available which are formulated and vetted by testing to take advantage of each compounds strengths and compensate for their weaknesses. Their activity against bacteria, fungi, and algae makes them good candidates as components of broad spectrum package for contamination prevention in paints.

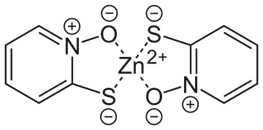

B. Pyrithiones, the Zinc complex of Pyrithione also known as ZPT (shown below) is an excellent anti-fungal agent and is widely used in coatings formulations as well as a wide variety of consumer products including cosmetic and personal care formulations. ZPT has good activity against both fungi and algae, good wet and dry stability, resistance to leaching, and tolerates pH in the ranges commonly encountered in coatings formulations. Care must be taken to avoid oxidizers/reducers and chelating agents such as EDTA as they can degrade the effectiveness of ZPT.

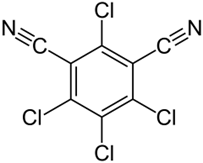

C. Chlorothalonil (see below), while an effective broad spectrum fungicide, may find its days in paints numbered. The EU and Switzerland have banned its use since 2019 and the US EPA is considered significant reductions to allowed levels in coatings applications in order to mitigate worker exposure to Chlorothalonil.

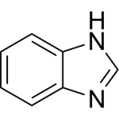

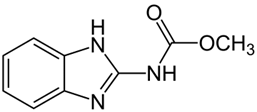

D. Benzimidazoles share the five-membered nitrogen heterocyclic ring with the other azoles but as the name implies, they incorporate a benzene ring into the basic structure (see below left). Carbendazim (see below right) is one of the more widely used fungicides in this class for coatings applications. It has some gaps in its fungicidal activity, but has excellent stability and longevity in both wet and dry paints. It is effective as a dry-film preservative to prevent the growth of fungi and algae. Carbendazim, also known as BCM, is often combined with isothiazolinones to increase broad spectrum efficacy.

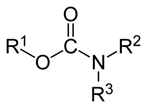

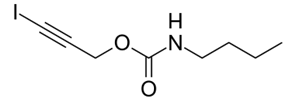

E. Carbamates have the basic structure shown below on the left. IPBC or 3-Iodopropynlbutylcarbamate (structure shown below on the right) is the most widely used dry-film preservatives in the coatings industry. IPBC is active against a broad spectrum of fungi at low dosages and has very good stability in paint and low leaching potential from the dry film which gives it long term efficacy. It is stable at temperatures up to 80º C and at acid and neutral pH conditions, but may hydrolyze under highly alkaline conditions.

F. Azoles are compounds with a five-membered ring containing at least one nitrogen and one other non-carbon atom. The other heteroatom is often nitrogen, oxygen or sulfur. Benzimidazoles discussed above are also members of this group, as are isothiazolinones but are usually treated separately in discussions of fungicides due to their wide commercial use in coatings. The primary uses of the other members of the azoles family are in agricultural products and they are uncommon in coatings formulations.

Formulating Effectively with Fungicides

There are three main concerns when utilizing fungicides in a paint formulation that must be addressed to ensure effective in-can and dry-film preservation. These include:

1.Choosing complimentary combinations to ensure efficacy against a broad spectrum of organisms. Some fungicides have gaps in their efficacy against certain groups of fungi. In order to achieve protection against contamination, a mixture of anti-fungal agents should be used. Solubility and persistence, in order to balance immediate efficacy with long-term effects stability and solubility must be considered. A stable fungicide doesn’t break down chemically due to exposure to conditions such as high temperature, UV radiation, or extreme pH. The solubility of a fungicide can determines its immediate efficacy vs. its longer-term effect. Highly soluble preservatives migrate to the coatings surface quickly and prevent contamination, but they can also be easily washed away. Fungicides with low solubility remain in the interior of the film and migrate to the surface slowly, providing longer term protection.

2. Regulatory acceptance for the target market in the regions of product distribution can sometimes be one of the most difficult parts of choosing a fungicide for your formulation. For example, DCOIT is banned from use in coatings in Canada but is used widely in the United States. Both DCOIT and OIT are regulated as strong sensitizing agents in the EU and are subject to increasingly strict regulations. In most regions the allowed amount of a fungicide in a paint formulation is regulated and the formulator is responsible for compliance wherever the product is distributed.

3.Testing to confirm the effectiveness of your formulation is the final step in selecting a fungicide package for your formulation. The last steps in any formulation development process is testing to ensure the product meets expectations. There are several standardized laboratory tests to determine the ability of a surface to resist fungal and algal contamination. Often, microbiology is outside the expertise of paint manufacturers and suppliers are relied on to perform these tests on the formulators behalf. A more DIY approach is the test fence. Whether at you own facility or at an outside exposure site. This approach takes longer but is economical and yields real world results.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.