Plastics have much to offer to provide a sustainable future. In September 2024, Andy Pye looked at some examples of positive contributions being made by the polymer industry. This update covers some more of the more groundbreaking developments.

Over 600 delegates recently attended the Global Research and Innovation in Plastics Sustainability Conference (GRIPS), which showcased the industry’s leading innovations working towards plastic sustainability and circularity.

Organized by Innovate UK alongside its partner, the British Plastics Federation (BPF), the fourth annual GRIPS conference featured presentations and panel discussions across three streams; sustainability, recycling and materials.

Reflecting on the event, Founder of the UK Circular Plastics Network and Knowledge Transfer Manager for Polymers at Innovate UK Business Connect, Prof. Sally Beken, said, “Plastics have undeniably shaped the modern world. From packaging which preserves our foods to medical supplies that save lives, plastics have been a cornerstone of innovation and convenience.” But we know this story has another side. Our dependence on plastic, particularly single-use plastics, has contributed to some of the most pressing environmental challenges of our time.

“GRIPS allows us to chart a sustainable future for plastics and explore how our industries, governments, and societies can address the challenges and opportunities that lie ahead. GRIPS 2024 has been no exception, and we’re pleased to have facilitated another year full of so much valuable insight from so many sectors.”

GRIPS saw the launch of Innovate UK’s new report “Sustainable Carbon Ambition for the UK Chemicals Industry”, which highlights the opportunity for the sector to diversify away from virgin fossil carbon and toward other sustainable feedstocks.

“This report shines a light on the need for industry and government to collaborate on creating a resilient chemicals sector.” said Dr Peter Clark, Head of Chemistry and Industrial Biotechnology at Innovate UK Business Connect. “A strong UK chemicals industry will be able to manufacture the sustainable ingredients that are in demand in downstream sectors, creating high value jobs and growing the economy.”

Discover Material Selection with Prospector Premium, learn more here!

Elsewhere, highlights included Co-Director of the University of Sheffield’s Grantham Centre for Sustainable Futures, Prof. Rachel Rothman, who spoke on waste hierarchy and projects such as ‘Many Happy Returns’ that are helping retailers and customers rethink their package use and incentivize reuse. CEO and Co-founder of Disposal, Sophie Walker, highlighted the importance of quality data in driving circularity and unlocking opportunities. Tesco’s Head of Packaging and Food Waste Strategies, James Bull, talked about the need for bespoke packaging solutions for every product to help maximize reuse and recycling.

Bioprocessing – balancing single use with sustainability

Single-Use Technologies (SUTs) offer numerous benefits, including faster setup and flexible process configurations, while significantly contributing to the reduction of resources like water, electricity, and caustic chemical usage. Although their waste contributes only about 0.002% to global plastic waste, an industry-academia collaboration to advance sustainable bioprocessing through innovative materials for additive manufacturing, also known as 3D printing, has also been announced by Innovate UK as part of the Sustainable Medicines Manufacturing Innovation: Collaborative R&D fund.

By utilizing advanced 3D printing technology and newly developed eco-friendly, bio-based resins to produce thermosets that can be autoclaved for reuse, Project Nexus aims to tackle current challenges and enhance sustainability through greater circularity – aligning with government targets for reducing waste and promoting sustainable manufacturing.

Work smarter and win more with powerful software to manage regulatory, supply chain and sustainability challenges, learn more about ULTRUS here!

Project Nexus is a collaboration between Photocentric, Sartorius, Metamorphic, CPI, the University of Sheffield and Imperial College London, is embarking on the development of new sustainable materials for application in single-use bioprocessing equipment such as bioreactors. It brings together extensive expertise across advanced manufacturing automation, digital design and optimization, as well as material innovation and bioprocessing, to pioneer the future of additive manufacturing (AM) of bioreactors at scale. The project aspires to offer a greener alternative to SU bioreactors with enhanced circularity and end-of-life pathways, all while retaining the flexibility of disposable systems.

Photocentric’s latest technology innovation, JENI – a fully automated digital mass manufacturing platform, will be utilised, alongside use of newly developed bio-based, eco-friendly materials. “Through harnessing the advanced capabilities of our latest 3D Printing innovation, JENI, we’re really excited to be part of this important partnership and the development of a new generation of cost effective, sustainable solutions for biopharma,” said Paul Holt, Founder and Managing Director of Photocentric commented.

Sustainable advanced composite storage tanks for hydrogen

Efficient storage tanks are key to decrease the cost of hydrogen usage in mobile applications such as commercial road transport, railway, construction, marine and aviation. Now, Japan is celebrating the commissioning of the first SAMBA Pro PV system in Japan. This advanced composite lay-up system, supplied by German automation specialist Cevotec, allows the Japanese manufacturing industry to develop lighter, more sustainable composite tanks with increased storage volume.

The SAMBA Pro PV system is based on Fiber Patch Placement (FPP) technology. It is dedicated to the production of dome reinforcements for hydrogen pressure vessels, enabling significant savings while reducing the weight, cost, and environmental footprint of composite tanks. The system includes a second operating mode tailored for free-form components such as advanced aerospace composites – an area where Japan’s industry also has long held a leading position.

Fuji Industries has played a pivotal role in this initiative, sponsoring and delivering this advanced technology at the National Composites Center Japan (NCC) in Nagoya. The company exclusively represents Cevotec in Japan and facilitates commercial projects, including prototype development and demonstrator production, tailored to the specific needs of Japanese manufacturers.

“By integrating this advanced composite lay-up equipment, Japanese manufacturers can enhance the benefits of FPP technology for efficient and automated composite production, strengthening their competitiveness in the global market”, commented Junji Yamada, President of Fuji Industries Co. Ltd.

The deployment of the system is a result of the longstanding collaboration of Cevotec with Fuji Industries. “This commissioning underscores the innovative spirit and collaboration of the international composite community. It expands technology portfolio of Japan to develop better composite hydrogen tanks, and we are looking forward to a fruitful collaboration with our industry partners in this exciting field”, comments Professor Akinori Yoshimura, Director of the NCC.

In parallel with these activities at the NCC, the Fraunhofer Institute for Casting, Composite, and Processing Technology (IGCV), which houses a SAMBA Pro Prepreg system in Augsburg, Germany, has recently strengthened its presence in Japan by establishing the Fraunhofer Innovation Platform for Fibers, Processing and Recycling Solutions at Innovative Composite Center, FIP-MIRAI@ICC, in Kanazawa. This platform facilitates local cooperation and supports both Japanese and German companies, including startups, in advancing composite technologies.

The special case of the automotive industry

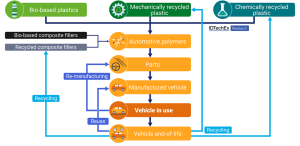

Automotive plastics face significant sustainability challenges, primarily in two areas: material sourcing and end-of-life processing. Most plastics used in vehicles today are derived from petrochemical feedstocks, resulting in high embodied carbon emissions and reliance on fluctuating fossil fuel markets. New regulatory pressures, including recycled content mandates and carbon taxes, push automakers toward sustainable alternatives. Recycled plastics and bioplastics are the two main alternatives, each with unique advantages and challenges. However, the widespread adoption of these materials depends on factors such as material availability, cost, and technical feasibility. For certain applications, integrating recycled plastics is relatively straightforward. For example, mono-material polypropylene interior components are already manufactured with recycled content. However, more specialized components from complex polymer blends and composites present greater challenges, particularly concerning end-of-life disposal and circularity.

Mechanically recycled plastics are the most widely available and the easiest to integrate into automotive manufacturing. These materials are produced by shredding, melting, and reforming waste plastics without altering their chemical structure. Regulatory mandates, such as the EU’s requirement for 25% recycled content in vehicles, are expected to drive significant market growth. Chemical recycling is another emerging solution that breaks down plastics into monomers or raw feedstocks, allowing for the restoration of material properties. However, chemical recycling remains in its early stages, with higher costs and infrastructure limitations slowing widespread adoption.

Bioplastics, derived from renewable biomass sources, offer another route to reducing dependence on fossil-based plastics. While promising, the bioplastics market is still nascent, with supply chain limitations and higher costs restricting adoption. The feasibility of integrating bioplastics into automotive manufacturing depends on the development of bio-based alternatives for key polymers, such as bio-polypropylene and bio-polyamide. While some automakers already incorporate bio-based materials into interior components and upholstery, scaling these solutions remains challenging.

Both recycled plastics and bioplastics are expected to experience strong growth in the coming decade.

IDTechEx’ latest report, “Sustainable Plastics for Automotive 2025-2035: Market, Players and Forecasts,” provides an in-depth analysis of sustainable plastic adoption in passenger vehicles. The report explores the entire circular economy of automotive polymers, including mechanically and chemically recycled plastics, bioplastics, bio-composites, sustainable upholstery materials, and sustainable tyre innovations.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.