Introduction

Flexibility is an important mechanical property of materials and coatings. Insufficient flexibility of a coating can have several causes and it can create a range of problems. This article focuses on the most common causes and possible consequences of internal stress. Also, some methods to prevent stress in coatings are discussed.

Film formation

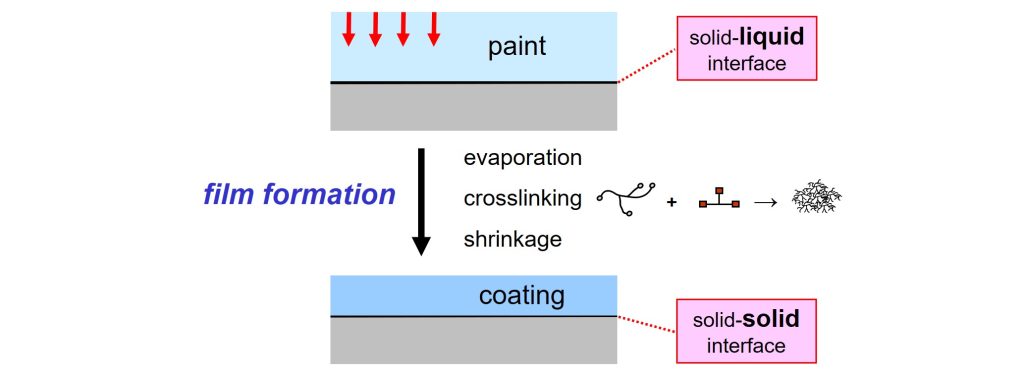

During film formation, a liquid paint transforms into a solid coating on a substrate. The process should proceed in such a way that a strong film results. The coating must adhere to the substrate and it should have the desired mechanical and protective properties. Two phenomena, that may take place during film formation, play an important role.

First, evaporation of volatile components, solvents and/or water, may occur. A film shrinks when molecules leave the system because of evaporation. Secondly, a chemical reaction within the binder system consisting of resin and crosslinker, called crosslinking, takes place in 2-component systems. Preferably, shrinkage only occurs in the direction perpendicular to the paint-air interface.

Causes of stress

Several phenomena can result in stress build-up in a coating. First, the adjustment of evaporation and crosslinking might not be optimum. Consider a system in which crosslinking is fast and evaporation is slow. A gel, a binder system with high crosslink density and low mobility, is formed when there is still a considerable amount of solvent present in the film. When evaporation continues, the voids that appear when solvent molecules leave the film, are filled with the binder system. Stress builds up when the binder system has limited mobility because of the high crosslink density, thus preventing relaxation.

In solvent-free, UV-curing systems, the binder matrix contracts because of reaction shrinkage. Even though the system does not loose material, because no evaporation takes place, stress builds up in the binder matrix during film formation. Background of this phenomenon is that the distance between molecules that contain reactive carbon-carbon double bonds (C=C) goes down when the chemical reaction, called radical polymerization, of such groups takes place during film formation.1,2

During the film formation of alkyd paints, a chemical reaction takes place of carbon-carbon double bonds (C=C) with oxygen from the air. This oxidative cure continuous, because the double bonds of the alkyd resin are not consumed during this chemical reaction. The crosslink density increases, as time goes by. Ultimately, the crosslink density becomes so high that the alkyd-based coating cracks. Also, the adhesion of the coating is lost.

Work smarter and win more, with powerful software to manage regulatory, supply chain and sustainability challenges, learn more about ULTRUS here!

A low amount of binder is present in systems that have a high loading of pigments and/or fillers. The demands, with respect to flexibility, of the binder system goes up when the Volume percentage of solid particles in a coating goes up.3,4

Stress can build up in a coating when the dimensions of the substrate change because of fluctuations in temperature and/or humidity or under the influence of mechanical force. Wood, for example, expands and shrinks when temperature and humidity change. Wood coatings, for that reason, must be flexible and only a limited degree of shrinkage should take place during film formation of a paint that is applied on wood.

In general, it can be said that stress builds up in a coating when the relaxation and flexibility of the binder system is insufficient to cope with the changes that take place within the coating itself or in the substrate.

Possible problems caused by stress

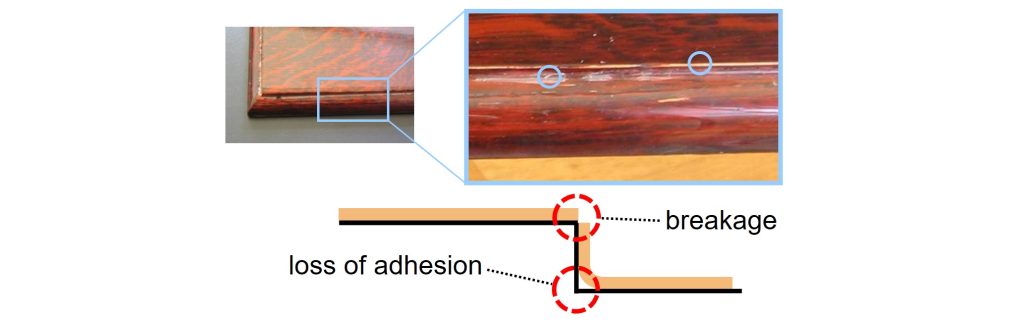

A variety of undesired phenomena can take place when stress builds up in a coating. Cracking of the coating occurs when the strength of the film is insufficient to cope with the stress.

A coating can break at sharp edges of the substrate. Also, the coating can be pulled loose from the substrate. Loss of adhesion is often called delamination.

Determination of stress

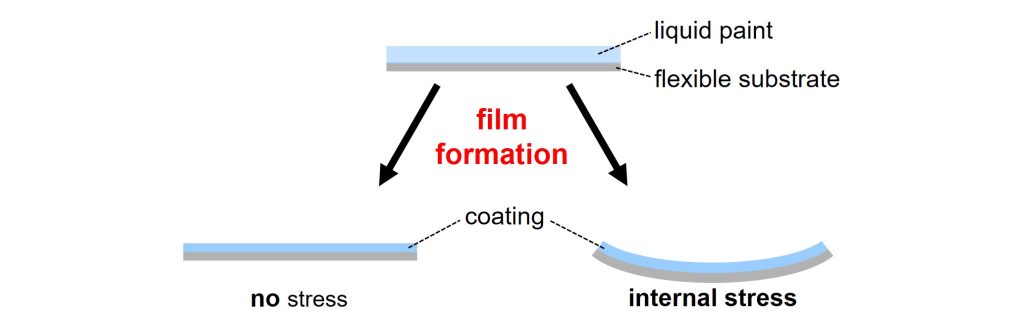

It might be difficult to determine whether or not stress builds up in a coating during film formation. In a simple test, a paint is applied on a flexible inert substrate. The complete system, consisting of substrate and coating, will curl when stress builds up during film formation.

Internal stress in coatings may expresses itself via film defects, like cracking, breakage, loss of adhesion and/or deformation of the complete system, consisting of substrate and coating.

Stress prevention

The most important attention points, with respect to the prevention of stress, are the binder system and the quality of film formation. In systems in which both evaporation and crosslinking take place, the two processes must be adjusted to each other. Stress in systems caused by reaction shrinkage can be reduced or prevented by using reactive flexibilisers in the system. In systems that contain a high loading of solid particles, stress can be reduced by using a more flexible binder system or by optimizing film formation.

Reinforcement, internal strengthening of a system, can be used in coatings by using solid particles with a non-uniform shape. Platelet-shaped mineral fillers, like mica or talc, are used to increase internal strength of coatings, thus improving crack resistance and adhesion. Fibers can also be used to reinforce a coating. CoatForce® CF10, for example, is a fiber-shaped mineral filler designed to increase the mechanical strength of coatings.

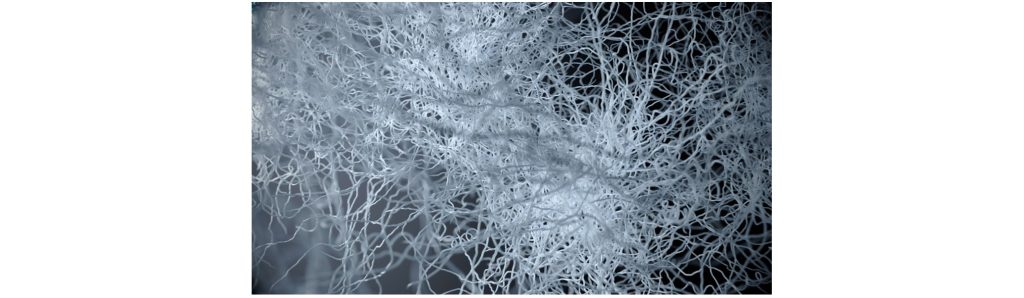

An interesting development is that biobased fibers are now available for coatings. Exilva® F 01-V for example, is a microfibrillated cellulose (MFC) that is used as additive to increases the internal strength of coatings. The thin fibers of MFC, called fibrils, entangle and form hydrogen bonds with binder molecules, thus reinforcing the coating.

References

- Radiation Cure Coatings – The Ultimate in Rapid Cure Technology, Ron Lewarchik, 2 April 2021.

- Using UV/EB Resins in Coatings, Marc Hirsch, 21 October 2016.

- Pigment Volume Concentration – Part I, Jochum Beetsma, 28 February 2020

- Effect of Pigment Volume Concentration on Coatings Properties – Part II, Ron Lewarchik, 15 August 2014.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.