John B. (Jay) Rogers likes to go big. To realize those dreams –– which he characterizes as nothing less than “shaping the future of AI-driven manufacturing” –– he needs big 3D printers. So he has aligned eight huge such machines in one space with the aim of making beautiful, eco-friendly furniture. On April 10 he and his team are pulling back the curtain on the very first microfactory for his fledgling firm, Haddy Inc., in St. Petersburg, Fla.

Haddy is dedicated to achieving full circularity through its lineage model for 3D printing and to using renewable and recyclable materials for all of its products. It says it “has built circularity into its foundation by upcycling products at end of use for the next generation of goods.”

At the firm’s grand opening, Haddy will showcase eight identical large-format additive manufacturing (LFAM) machines from Netherlands-based CEAD B.V. “We have the largest installed base of CEAD systems in the world,” says Rogers, a former U.S. Marine captain. These machines feature a build bed measuring 40 feet long by 9 feet wide by 9 feet tall. They move linearly, in six axes, and are equipped with Comau robotic arms.

Rogers –– who co-founded and for 14 years was CEO of Local Motors, a maker of 3D-printed vehicles –– co-founded Haddy in late 2021. The firm, whose name is an acronym for Heroic Agile Design Durable and Yours, opened its St. Pete headquarters in 2023 with two CEAD machines. It since has added six more, while leveraging machine learning and artificial intelligence (AI) to constantly improve its digital manufacturing processes.

A Microfactory Approach

Their business model, he said in a recent phone interview, calls for creating strategically located microfactories in any place that has a lot of people but not much local labor for making furniture. In the U.S. that includes places such as Chicago and Los Angeles as well as more broadly in Texas, the Mid-Atlantic region and the Pacific Northwest. Internationally, he’s eyeing Rotterdam in The Netherlands (with its excellent port and highway system) and northwestern Saudi Arabia. The goal is to stimulate local manufacturing to reduce shipping and related carbon emissions.

These places are all hungering for advanced manufacturing. Each microfactory is expected to cost roughly $8 million and stands to benefit from declining costs for industrial robots.

Discover Material Selection with Prospector Premium, learn more here!

After a long stint in the automotive industry, why furniture now? “I love the rapid pace of product development without needing tooling,” he explained. He also no longer wants to deal with long supply chains. With a car, he noted, your entire production can be held up by something as basic as a wire harness. “I wanted it all under one digital roof.”

Using large-format additive manufacturing, Rogers says Haddy can make better, faster, more durable products that also are less expensive and more sustainable. Being fully recyclable, they won’t end up in a landfill like so much used furniture does today.

The timing couldn’t be better for Haddy Inc., which is opening its first microfactory in St. Petersburg, Fla., on April 10 to 3D print sustainable furniture in the United States. The low-cost locations in Asia that produce most of the furniture sold in the U.S. are about to get hammered with hefty tariffs, making such imports significantly more expensive and jeopardizing long-established supply chains. In light of these circumstances, Haddy CEO and founder John B. Rogers makes his company’s case for digital domestic manufacturing in this April 8 LinkedIn post.

The company currently produces large pieces of furniture –– tables, chairs, architectural components –– for residential, commercial and hospitality customers., and intends to focus on architecture and design for the near future. Its retail customers currently include firms such as Minneapolis-based Room & Board and Detroit-based Gardner White Furniture.

Materials are Key for LFAM

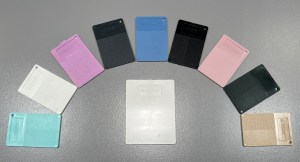

Haddy now uses primarily polyethylene terephthalate glycol (PETG), polycarbonate (PC) and the bioresin polylactic acid (PLA), along with bio-based fillers. Rogers says he’s had to learn a lot about materials and fused granular fabrication since embarking on this venture. But he’s had some solid support.

Clinton, Tenn.-based compounder and material design specialist Techmer PM is working closely with Haddy.

Rogers stresses that resin consistency for LFAM is vital, especially when one needs 200 kg of material just to even do a test run.

Jenna Hunt, Techmer’s business manager for engineered compounds and additive manufacturing, commented recently on the partnership.

“To monitor consistency in recycled product, we check color through yellowness index and incoming intrinsic viscosity (IV). It comes in as a flake, which we grind to a powder to ensure consistency in shape and feeding.

“Additionally,” she added, “to ensure that Haddy can rely on the quality of every lot of our material, we conduct physical testing, chemical composition testing, pellet geometry verification, and IV testing.” Techmer reviews all additive manufacturing products to ensure lot consistency due to the criticality of feeding needed in 3D printing.

Color is another challenge, Hunt noted. “Color matching PETG is more difficult than PE, PP or PLA due to its higher processing temperature. This can limit which pigments can be used since they may not take the temperature and can shift in color or even lose all their color.”

This year, marked by the official opening of its St. Pete microfactory, Haddy aims to lay the groundwork for steady growth. Then, in 2026, Rogers says, they “intend to come out swinging.”

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.