EDITOR’S NOTE: Part 2 of 2 by Robert Grace (Part 1 available here)

Several companies discussed a host of new initiatives and products during European Marketing Group’s recent media event in Rotterdam, The Netherlands. The June 4-5 sessions allowed the firms to showcase what they intend to focus on at the massive K 2025 trade show in Düsseldorf, Germany, from Oct. 8-15.

Here are a few highlights from those presentations.

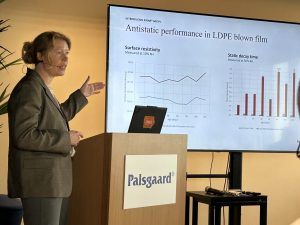

Palsgaard A/S (K 2025 Booth C15, Level 1, Hall 7)

Palsgaard A/S, the Danish maker of plant-based additives for the plastics industry, continues to broaden its portfolio of products, which it will display at the K 2025 show.

At EMG’s pre-K event in Rotterdam last month, company officials focused on the introduction Einar® 987, a plant-based anti-fouling additive specifically designed for polypropylene and polyethylene polymerization processes. A clear, viscous liquid, the product is a polyglycerol ester (PGE) blend of fatty acids from vegetable oils. As a non-toxic and food-contact-approved, anti-fouling additive, it offers a drop-in, regulatory-compliant solution to replace the incumbent ethoxylated amine (EA) chemistry.

Laura Juhl, application manager of polymer bio-specialty additives at the 108-year-old Palsgaard, said at the event that the company has conducted several successful trials of this new additive, with one polymer producer having already approved it for use.

Palsgaard also recently commercialized Einar® 608, which can perform dual functions that reduce both hot and cold fogging in polyethylene films while also acting as an anti-static agent in the injection molded process.

Based in Juelsminde, Denmark, Palsgaard is busy expanding production capacity in its home country, as well as in The Netherlands, and has plans to invest in Malaysia by 2028, according to Ulrik Aunskjær, director of bio-specialty additives.

Kisuma Chemicals (Booth H31, Hall 8B)

Kisuma Chemicals, a leading producer of magnesium-based additives, used the Rotterdam event to spotlight its introduction of Setogem™ RD, a dual-function nucleating agent and acid scavenging agent for polypropylenes. Based in Veendam, The Netherlands, Kisuma Chemicals is the European arm of Japan’s Kyowa Chemical Industry Co. Ltd.

Samir El Khoury, regional business manager for the Middle East and Africa and global product line manager for polyolefin additives, said the dual functionality of this new molecule “allows polyolefin producers to reduce the complexity of their additive formulations while offering improved performance and a reduced specific migration limit (SML) solution for the industry.”

He said the nucleation performance of Setogem™ RD helps resin producers promote and control the formation of crystals within the polymer, resulting in polypropylene (PP) materials with outstanding stiffness, impact strength and isotropic shrinkage. It also provides excellent heat-deflection temperature and low creep deformation.

Meantime, El Khoury said that its acid-scavenging property offers non-migratory performance even at low use levels. This helps to reduce blooming and migration, which is critical for medical and food-contact applications facing strict regulatory demands.

Being zinc-free, Setogem™ RD reduces the need for tallow or palm oil derivatives and allows customers to reduce the loading levels compared to other, less sustainable additives from several kilograms per ton of PP to only 200 or 300 ppm.

The company plans to launch another new molecule by the K Show in October, El Khoury noted. It also plans to roll out a next-generation flame-retardant solution.

Syensqo (Booth C61, Hall 6)

Brussels-based advanced materials and specialty chemicals maker Sysenqo, which spun off from Solvay SA in late 2023, will be showcasing its new identity at K 2025, along with a brightly colored new resin targeting the e-mobility sector. At the Rotterdam event, it chose to highlight a new grade of its Amodel®-brand polyphthalamide (PPA) that is distinguished by its stable and vibrant orange color.

Amodel® PPA HFFR-4133 OR is a 33% glass fiber-reinforced, halogen-free, flame-retardant PPA resin. Its bright color aligns with the aim to emphasize safety and visibility for critical electric vehicle (EV) components such as connectors and busbars, noted Nicolas Batailley, marketing manager – transportation.

He displayed several key materials for automotive, including its award-winning Ajedium™ PEEK film for slot liners and Ketaspire PEEK for magnet wires in electric vehicle motors. “We now offer Ajedium™ films based on our ISCC PLUS mass-balance-certified Radel® PPSU ECHO grade, produced with 100% renewable electricity.”

Paul Blondeau, semicon market segment leader, discussed how Syensqo materials play a key role in nearly every semiconductor process –– from its Solef® PVDF for ultrapure water piping to Tecnoflon® PFR FFKM for O-rings. Various Syensqo polymers also offer solutions in multiple smartphone applications.

Philippe Brasseur, a senior customer technical development manager, outlined various consumer product applications, including how the firm’s Radel® PPSU is ideal for medical-grade products such as sterilization-resistant surgical tools.

The company said it aims to develop a “carbon-neutral future,” specifically via its ECHO portfolio that draws on bio-based and recycled materials.

OQ (Booth A23, Hall 6)

OQ, Oman’s global energy group, says that at K 2025 it will be featuring 17 new application-focused polymer grades that it has developed over the past year. These products are aimed at addressing global megatrends such as food preservation, water security, and energy saving.

As for the recently developed products, Dr. Abdul Rahman Al Tamtami, vice president of global marketing, said they include:

- 6 PP impact copolymers for rigid packaging applications including thin-walled packaging, housewares and durables. He said these –– notably its Luban EP2348T grade –– offer excellent flow and stiffness-impact balance.

- 4 PP random copolymers that provide enhanced transparency and organoleptic performance. These –– including its Luban RP2251T grade –– are said to be ideal for housewares, closures, and food containers.

- 2 PP homopolymers that OQ has tailored for spunbond nonwoven applications. These offer superior fiber strength and processing stability.

- 5 polyethylene grades, including a rotomolding grade (Luban LL-8446.21), that they developed for water storage and road-safety applications. These are said to deliver excellent impact, durability and UV resistance.

OQ also has partnered with Milliken Chemical to develop three new PP grades for rigid packaging. They designed these materials using Milliken’s proprietary clarifiers and additives.

Additionally, company officials provided an update on progress related to the Ladayn Polymer Park in Oman. Mundhar Al Rawahi, head of the Ladyn program, told journalists that four companies are now expected to begin production this year in the industrial park, which is designed to bring value-added plastics manufacturing to the country. These four companies represent an investment of $54 million and will produce everything from form/fill/seal bags to advanced polymers for heat resistance and surface protection.

Discover Material Selection with Prospector Premium, learn more here!

Since plans for the initiative were announced in 2023, some 18 companies have committed to invest a total of $160 million in the park, many of which are converters that will use OQ’s PP and PE resins.

MOL Group (Booth C20, Hall 5)

Budapest, Hungary-based MOL Group prides itself on being an international and fully integrated oil, gas, petrochemicals and consumer retail operation. Founded in 1991, the 24,000-employee enterprise serves more than 1,400 customers in nearly 40 countries.

The firm operates three production sites that manufacture more than 2 million tonnes per year of chemicals –– base chemicals (800,000 tonnes per year), polyolefins (1.1 million tonnes) and polyols (200,000 tonnes).

Peter Császár, MOL Group Chemicals senior vice president, noted that MOL is backward integrated and, based on a 35-year agreement that began two years ago, now manages all of Hungary’s waste streams, which total 4.7 million tonnes of municipal solid waste per year. It intends to produce up to 1.5 million tonnes of feedstock for the energy industry by 2030.

Krisztina Petrényiné Szabó, MOL Group’s polymers business director, said that, when it comes to enhancing productivity, MOL has seen a $100 million positive impact from its portfolio restructuring and from increased energy efficiency.

Looking ahead, she says MOL is investing $2 billion to boost its chemicals production capacity by 400,000 tonnes. Propylene capacity will be increased by 100,000 tonnes per year (to 440,000 tonnes) by 2026, and polypropylene will be boosted to 535,000 tonnes per year. It is increasing maleic anhydride capacity to 50 tonnes, making it the third-largest supplier in Europe.

Polyvantis GmbH (Booth D27, Hall 8B)

Polyvantis GmbH wrapped up two days of presentations in Rotterdam with CEO Sandeep Dhawan offering a brief company history and a look at what lies ahead. The Germany-based firm was created last year via the merger of Röhm’s acrylic products business unit and SABIC’s functional forms business.

The new entity boasts some of the best-known brand names in the industry, including the polymethylmethacrylate (PMMA) brands of Plexiglas® and Acrylite® from the former Rohm portfolio, and the polycarbonate (PC) Lexan™ brands from SABIC. Polyvantis offers products such as films, sheets, and pipes and rods, serving a multitude of segments, ranging from automotive, rail and aerospace to medical, lighting, signage, safety/security and electronics.

Dhawan said the firm will showcase a pair of new products at the Düsseldorf trade fair, including a new glass fiber-reinforced PC sheet product, Lexan™ F8000HR, targeting the aircraft interiors market. The company claims this lightweight sheet “offers unrivaled performance, and value compared to other fully FST-compliant aircraft interior materials,” while also exhibiting exceptional thermoforming capabilities.

The other new product introduction will be a film for microfluidic applications in the healthcare sector, though Dhawan declined to offer any further details ahead of the show.

With about 1,500 employees and 15 production sites across the Americas, Europe, Asia, and Africa, Polyvantis sees continued growth in the largely “recession-proof” healthcare sector, as well as in the digital printing market, which Dhawan sees doubling by 2030.

___________

Click here to see Part 1 of this report, covering news from six other companies.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.