Petrol-based plastics are present in many aspects of our daily lives, from clothing to food packaging. They are often left behind in the environment, where they degrade, breaking into thousands of tiny pieces that harm ecosystems and human health.

Bioplastics will be needed to sustainably supply the increasing demand for polymers without increasing the use of petroleum-based plastics. Plastics and polymers need to achieve both desirable performance in terms of durability and strength, as well as triggerable degradation capability to enable their breakdown.

Are biodegradable bioplastics meeting their promise?

In IDTechEx’ latest market research report on the topic, “Bioplastics 2025-2035: Technology, Market, Players, and Forecasts”, the full spectrum of plastics derived from biobased feedstocks is discussed by author James Kennedy, including biodegradable plastics, such as poly-lactic acids (PLAs) and polyhydroxyalkanoates (PHAs). See Reference 1

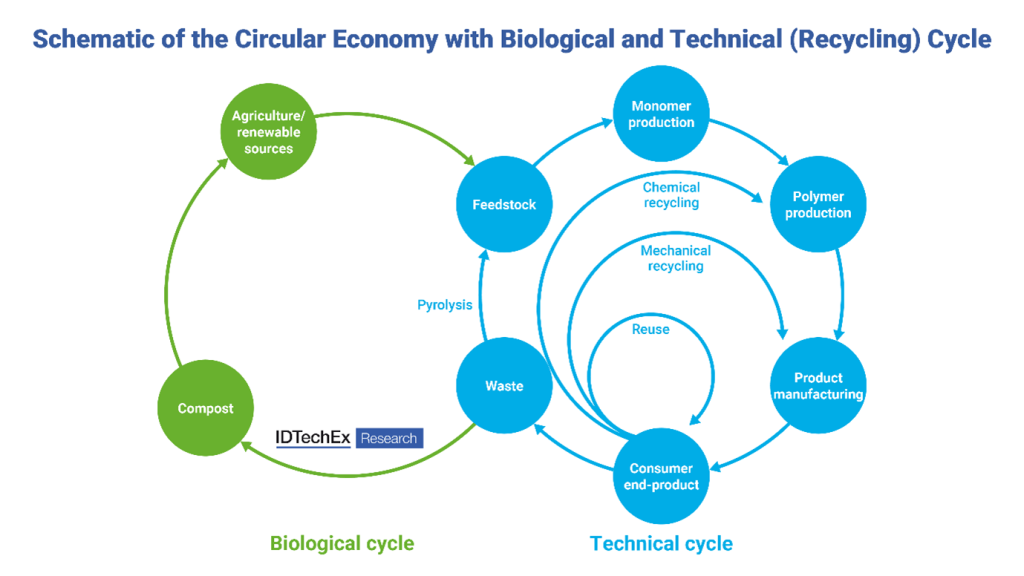

The carbon emissions of plastic production can be significantly reduced by using bio-based feedstocks due to carbon sequestration in the polymer during production. In addition, certain biodegradable bioplastics will have an increasing role in the circular economy. Under the correct conditions, polymers such as PLA or PHAs can be composted to tackle the growing challenge of plastic waste.

While biodegradable plastics are seen as a potential solution, their production remains limited, accounting for just 1.3 million tons in 2022 compared to 400 million tons of petrol-based plastics. Many so-called biodegradable plastics also fail to biodegrade efficiently under all environmental conditions such as soil, rivers, and oceans.

The IDTechEx report notes that one of the hurdles to the adoption of any new technology is overcoming market inertia, the resistance to change. Drivers are key in this process, and none has been so disruptive as actions taken in China restricting the use of single-use petrochemical plastics. In response to this government action, the Chinese market has seen a huge increase in large-scale factories producing PLA and other biodegradable bioplastics. Other governments around the world have been exploring and implementing similar actions further expecting to strengthen the growth of bioplastics that are used in single use applications.

Discover Material Selection with Prospector Premium, learn more here!

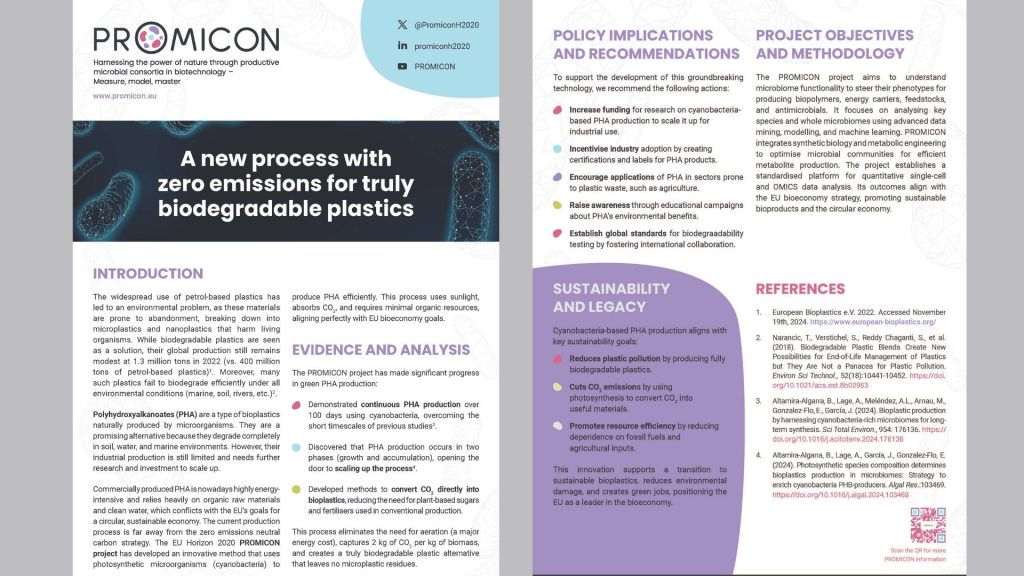

Europe’s Horizon 2020 PROMICON project

Researchers from the Horizon 2020 project PROMICON have developed an innovative method that leverages photosynthetic microorganisms (cyanobacteria) to produce polyhydroxyalkanoates (PHA) – a type of bioplastic that fully degrades in soil, water, and marine environments. PHA is naturally produced by microorganisms, but scaling up its production remains a challenge:

‘Commercially produced PHA is nowadays highly energy-intensive and relies heavily on organic raw materials and clean water, which conflicts with the EU’s goals for a circular, sustainable economy. The current production process is far away from the zero emissions neutral carbon strategy.’ – explain the authors of PROMICON’s policy brief.

The new approach for PHA production proposed by researchers from the Polytechnic University of Catalonia uses sunlight, absorbs CO2, and requires minimal organic resources, creating a truly biodegradable plastic alternative that leaves no microplastic residues.

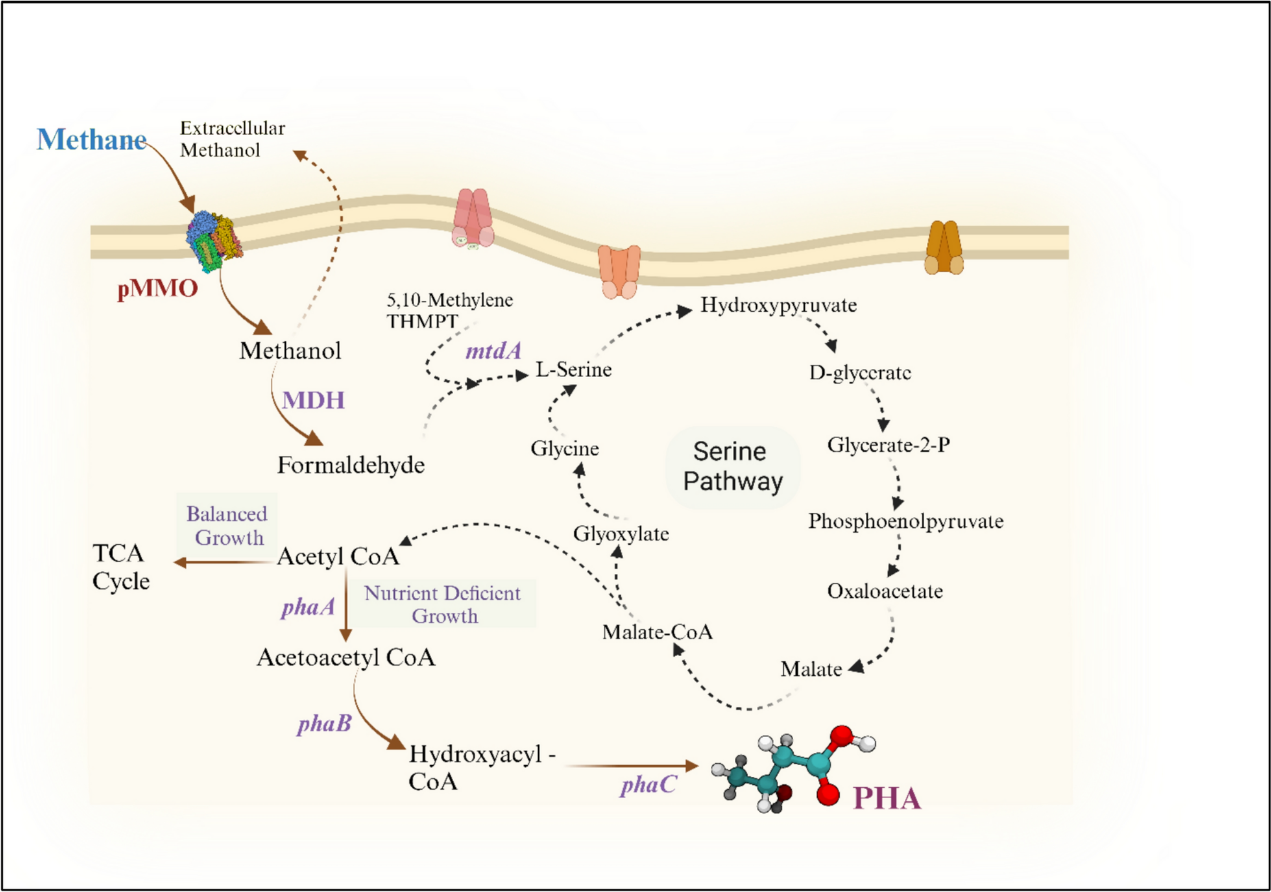

Methane-munching microbes

With similar objectives, growing interest in the abatement of greenhouse gases has spurred a surge in research within the field of methanotrophy in recent decades. Certain methanotrophic organisms exhibit the unique ability for the production of biodegradable polymers known as polyhydroxyalkanoates (PHAs) using methane as their solitary carbon source – see Reference 2.

Through genomic analysis of the bacterium, a research team at the BioWRAP Consortium of the South Dakota School of Mines and Technology has discovered four distinct genes responsible for producing PHA synthase, a critical enzyme in plastic synthesis. Advanced protein modelling and molecular docking have revealed how these enzymes efficiently bind substrates, with hydroxybutyrate and hydroxydodecanoate showing the strongest interactions.

The resulting plastic matches commercial quality, displaying a melting point of 188°C and a distinct infrared signature confirming its structure.

This breakthrough not only converts methane – a potent greenhouse gas – into an eco-friendly material, but also overcomes key industrial bottlenecks. The natural adaptability of methane-consuming bacteria to low methane environments, opens the door to scalable, cost-effective bioplastic production, bridging the gap between waste gas recycling and sustainable manufacturing.

Oxo-biodegradable plastic

Over 25 years, Symphony has developed a biodegradable plastic technology which addresses the problem of persistent microplastics, by turning ordinary plastic at the end of its service-life into a waxy substance which is biodegradable. It is then no longer a plastic and can be bioassimilated in the open environment in a similar way to a leaf without leaving microplastics behind. The technology is branded d2w. The technology is classified as oxo-biodegradable, involving both oxidative and microbial degradation processes that result in full biodegradation without leaving toxic residues or persistent microplastics.

Symphony Environmental’s d2w oxo-biodegradable plastic technology has received approval in the Republic of Ireland, a member-state of the European Union.

According to the company, “Following a thorough review of the submitted documentation and relevant scientific studies, we can confirm that d2w products do not contain oxo-degradable or oxo-biodegradable materials as defined by Directive (EU) 2019/904, which prohibits the use of oxo-degradable plastics due to their contribution to microplastic pollution. Furthermore, we have reviewed the Commission Notice (2021/C 216/01) published in the Official Journal of the European Union on 7 June 2021, which provides guidelines on the implementation of Directive (EU) 2019/904.”

Symphony’s d2w masterbatch technology is added to polyethylene (PE) and polypropylene (PP) products at the manufacturing stage at little or no extra cost, and ensures that if they get into the environment at the end of their useful life they will not create microplastics and lie or float around for decades. Instead, they will safely biodegrade, leaving no microplastics or toxicity. If they get collected during their useful life they can be recycled with ordinary PE and PP without separation.

According to the Office of Environmental Enforcement of the Environmental Protection Agency in the Republic of Ireland, based on the evidence submitted, the Agency has declared that it is satisfied that d2w products do not fall within this category, as they are designed to undergo full biodegradation without leaving microplastics. Therefore, they are not subject to the restrictions outlined in the Directive or its accompanying guidelines.

“We are very pleased to receive official approval from the government of a member-state of the European Union for the sale and use of products made with our d2w oxo-biodegradable technology,” said Michael Laurier, CEO of Symphony Environmental. “We see no reason why it should not now be sold and used in every member-state of the EU. We are confident that it is better for Europe’s environment for plastic to be made so that it quickly biodegrades leaving no toxic residues, instead of lying or floating around for decades and creating microplastics.”

Elsewhere, the Supreme Federal Court (STF) of Brazil has upheld Complementary Law 233/2008. This ruling requires the use of reusable or biodegradable or oxo-biodegradable plastic bags in commercial establishments in the City of Piracicaba (pop.440,000), marking a significant victory for environmental sustainability. This ruling has national implications, confirming the validity of similar laws across Brazil.

The fact that it mandates oxo-biodegradable bags is particularly important, because the main problem with plastic is that it creates microplastics and can lie or float around for decades. Oxo-biodegradability solves this problem because it makes the bags safely biodegrade much more quickly if they escape into the open environment.

Biodegradable nylon precursor produced through artificial photosynthesis

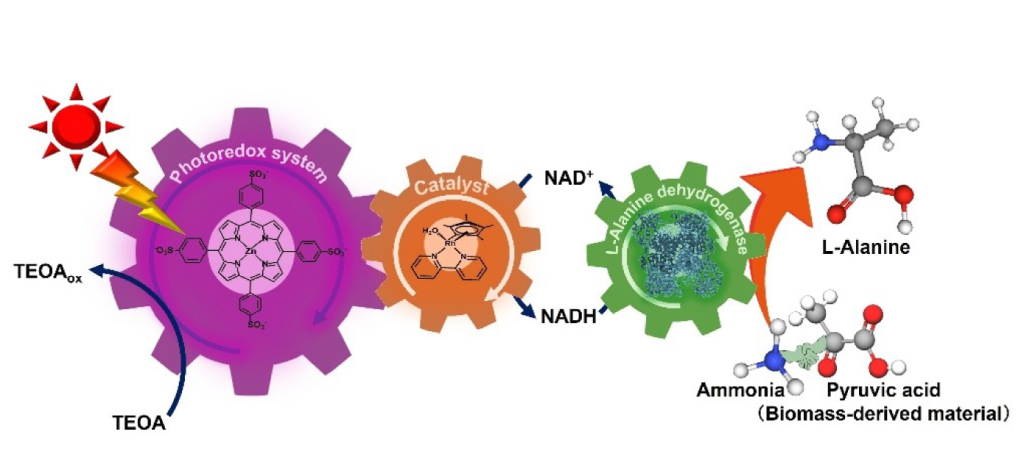

Meanwhile at the Osaka Metropolitan University in Japan, biodegradable plastics based on biomass-derived compounds as an alternative to conventional plastics are being investigated. Scientists have now synthesized biodegradable nylon precursors. Nylon is currently made from chemicals found in fossil fuels.

Professor Yutaka Amao’s team at the Research Center for Artificial Photosynthesis have previously reported on a method for producing raw materials for biodegradable plastics from biomass-derived compounds. A polyester-type biodegradable plastic could be formed by using L-lactic acid as the raw material for polylactic acid.

This time, by using L-alanine, an amino acid with a similar structure, the team created raw material for a nylon-type biodegradable plastic. Artificial photosynthesis technology was developed with the addition of the biocatalyst L-alanine dehydrogenase, which combines ammonia with pyruvate to produce L-alanine, to the photoredox system composed of a dye and a catalyst.

“We have also succeeded in synthesizing the precursor of biodegradable nylon poly-L-alanine using solar energy,” Amao declared. “In the future, we hope to achieve the synthesis of nylon precursors that have a low impact on the environment, with the aim of producing L-alanine through artificial photosynthesis using ammonia derived from biomass compounds.”

The findings were published in Sustainable Energy & Fuels.

Moveable crosslinks – a tradeoff between properties and ability to degrade

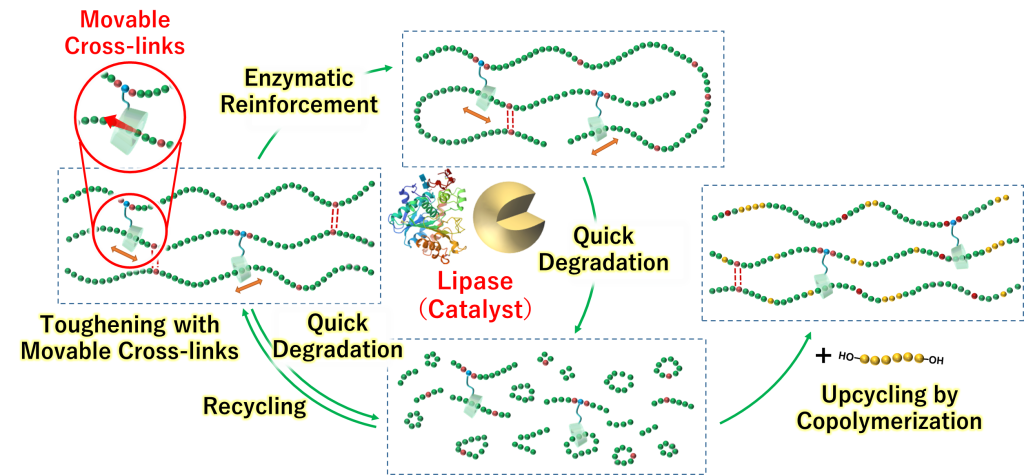

Also in Osaka, Japan, researchers from Osaka University have produced plastics with both improved toughness and biodegradability by including movable ring-based crosslinks.

The researchers have revealed that developing polymers with movable crosslinks not only increases their strength but also promotes degradation by enzymes under mild conditions.

At present, there is a trade-off between these factors – increased toughness makes the polymer more difficult to degrade. The researchers have used movable crosslinks to resolve this problem.

The movable crosslinks are ring-like cyclodextrins, which are threaded on one polymer strand and attached to another, endowing the resulting plastics with increased toughness and durability. Cyclodextrins are non-toxic, biodegradable, and widely available, making them attractive as a polymer component.

“Our polymer design using movable cyclodextrin crosslinks increases polymer toughness by over eight times,” says lead researcher Jiaxiong Liu. “Stiffness, ductility, fracture stress, and fracture strain all improve because the cyclodextrin groups effectively dispersed local stress.”

But because their bulky structure increased the free volume in the polymer network, cyclodextrin crosslinks also facilitate degradation of the polymers during subsequent enzymatic treatment This is due to improved access of the enzyme to the target cleavage sites on the polymer chains. See reference 3.

“The polymers are readily degraded by Novozym 435, an enzyme that specifically attacks the ester bonds of the polymer backbone,” explains senior researcher Yoshinori Takashima. “The presence of the bulky cyclodextrin crosslink groups decreases entanglement and aggregation of the polymer chains, which facilitates the access of the enzyme to the ester bonds for cleavage. As a result, biodegradability is improved by 20 times, compared with that of the same polymer without cyclodextrin groups.

References

1 1 “Bioplastics 2025-2035: Technology, Market, Players, and Forecasts”. IDTechEx

https://www.idtechex.com/en/research-report/bioplastics-market-2025/1032

2 Eleni N. Moutsoglou et al. Department of Chemical and Biological Engineering, South Dakota School of Mines and Technology. Methylocystis suflitae as a promising industrial workhorse for methane-based polyhydroxyalkanoate production, Systems Microbiology and Biomanufacturing, Dec 29, 2024. https://doi.org/10.1007/s43393-024-00324-1

3 Jiaxiong Liu et al, Department of Macromolecular Science, Graduate School of Science, Osaka University. “Exploring enzymatic degradation, reinforcement, recycling, and upcycling of poly(ester)s–poly(urethane) with movable crosslinks”, Chem, Volume 11, Issue 2102327, (February 13, 2025)

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.