If you imagined the perfect paint for your building you would want it to have the following properties. First, it should be long lasting, fade resistant, and protect the substrate from the ravages of moisture, pollution and microbial growth like algae and fungi. Low VOC content and water-based technology is essential for any coating to comply with current environmental regulations and sustainability goals. Application and adhesion to a wide range of building materials are also must-haves. What if I told you that such a coating has been in wide use since the 1880’s.

Enamored by the beautiful lime frescoes of Italy, King Ludwig the first of Bavaria wanted to bring their beauty to his own northern alpine kingdom. Alas, the harsh climate proved too extreme for the fragile artwork. Ludwig encouraged the chemists of the time to develop a coating which would rival these frescoes in appearance but be resistance to the climate of the German Alps. In 1878, Adolf Wilhelm Keim (shown below) was granted a patent for silicate-based paints for use on stone and masonry. The company he founded, Keim Farben (from the German for colors) is still in business today, headquartered near Augsburg in the state of Bavaria.

Let’s spend some time together learning about how silicate paints form a coating, what they do to protect a surface and how they are formulated. I’ve learned a lot about them researching and writing this article and I hope you find it interesting and informative as well.

Coating Formation in Silicate Paints

Most silicate paints are waterborne systems and I will only discuss those systems in this article. The mineral based binder systems used in silicate paints may contain no to very small amounts of organic constituents, this makes for very low VOC content in a waterborne coating. Because they are mineral based, silicate paints are limited to chemically similar substrates such as concrete, stucco (render), brick, natural stone, and fiber cement board. Their water permeability prevents moisture build up in the structures they protect. The high pH and mineral content of silicate paints makes them naturally resistant to fungal and algal growth while their hardness imparts high dirt pick up resistance. The high pH means that silicate paints require more care in handling and application than other waterborne paints.

Work smarter and win more, with powerful software to manage regulatory, supply chain and sustainability challenges, learn more about ULTRUS here!

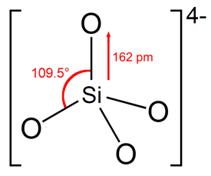

The primary binder systems of most silicate paints are based on the orthosilicate ion (structure shown below). Salts of Potassium are most common with Sodium salts also used. Silicate binders are comprised of polymeric chains of orthosilicate ions. As water evaporates and the paint cures, these chains increase in length and form a tightly packed coating over the substrate. A pure silicate paint such as this requires skill in preparation and application. Around 1950, a stable one-component silicate paint was developed by blending in organic additives such as acrylic latexes to form dispersion silicate paints. In 2002, colloidal silica was incorporated into silicate paints it give sol-silicate paints. This latest development made silicate paints easier and safer to apply to a wider variety of substrates.

Formulation Ingredients Utilized in Silicate Paint

Formulating silicate paints requires a new tool box of raw materials that you might not be familiar with from your previous experience. Utilizing a materials database like ULProspector is essential when formulating in this unfamiliar territory. Not only can you find technical data but starting formulas and informative articles as well. The process is similar to developing any new coating. Start by finding binder candidates based on your desired properties, determine possible pigments and extenders, and finally look for additives which will enhance your formulation. Binders are the area where silicate paints differ the most from coatings based on polymeric binders.

Binder systems

Silicate paints use relatively simple binder systems consisting of various sodium or potassium salts of polymeric orthosilicate ions. The first silicate paints were made from water glass or sodium metasilicate which is still in use today. Paints based solely on water glass must be handled carefully due to the high pH and caustic nature of the material. Organic co-binders like acrylic latexes and colloidal silica (Sol Silicate) were first used to increase stability and simplify application of silicate paints. These modified silicate paints are now the most commonly used because of the enhanced stability and safer handling characteristics.

Pigments

Due to the mineral nature of the matrix of silicate paints, inorganic pigments should be used. While this might seem limiting at first, there are many advantages to these materials. Inorganic pigments are by and large very light stable so paints made with them are very fade resistant. Both naturally occurring and synthetic inorganic pigments such as Red Iron Oxide and Bismuth Vanadate can be used. Mixed Metal Oxide Pigments, also known as Complex Inorganic Colored Pigments are great choices for high performing silicate paints. These synthetic inorganic pigments are not only more stable than other types of inorganic pigments, but many are reflective in the Near Infrared. These types of pigments are very useful in making heat reflective coatings for energy saving applications.

Additives

Like other types of coatings, silicate paints make use of additives to improve properties ranging from rheology to surface wetting. Many of these additives are the same as used in other types of waterborne coatings with the qualification that they must be stable at pH levels as high as 12. Wetting agents such as phosphate surfactants can be used to improve flow and ensure the coating covers the substrate evenly. Rheology modifiers, especially modified cellulose esters, thicken silicate paints to improve application properties like brush and roller loading, roller spatter, and sag resistance.

Summary

Writing this article has been eye-opening for me. I’m encouraged to expand my coatings formulation horizons by investigating the possibilities of silicate paints. They are used and trusted worldwide for their durability. Silicate paints can have a service life of up to one hundred years before repainting. Many landmarks and UNESCO World Heritage Sites around the globe are protected with silicate paints including the White House, the Houses of Parliament, Neuschwanstein Castle (the inspiration for Cinderellas Castle) and the Brandenburg Gate in Berlin. As Ashford & Simpson wrote they are “Solid, Solid as a Rock”.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.