Vessev, an Auckland, New Zealand-based company, is seeking to redefine sustainable marine transportation by leveraging lightweight composite technology to create its new, all-electric hydrofoiling boats. The first model –– the VS–9 –– is a 9-meter-long passenger vehicle that went into commercial service in Auckland in January.

Now it is actively eyeing the huge American market with plans to manufacture its keels there after appointing marine technology veteran Josh Trout earlier this year as its Rhode Island-based director of Vessev USA.

Fullers360, New Zealand’s largest ferry transport and tourism operator, on Jan. 30 began using the boat to carry passengers on tourism trips across Auckland’s waterways. This marked the first time ever that a certified electric hydrofoiling vessel has entered the fleet of an operator for commercial services.

The VS–9 can transport up to 10 passengers and provide an experience that Vessev says “is more like flying than sailing.” Its highly efficient, state-of-the-art hydrofoiling technology borrows heavily from proven racing technology. (New Zealand, after all, introduced modern hydrofoiling to the world in the 2013 America’s Cup.)

These vehicles, designed for commercial operations and tourism, represent a quieter, more efficient, and sustainable option for sea travel.

Carbon fiber and Epoxy Composites

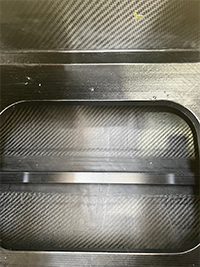

Garry Jolliffe, the firm’s chief operating officer, notes that the VS-9 is built primarily from carbon fiber/sandwich/epoxy laminates fabricated from resin infusion. Jolliffe previously served as principal engineer at Auckland-based VMG Composites Ltd.

Vessev makes the skins from a mixture of lightweight woven and non-crimped materials in the 200-800 gsm range. And they source the reinforcements from a number of global manufacturers via local distributors in New Zealand. The firm uses Gurit M-foam (a marine-grade styrene-acrylonitrile polymer) from Switzerland’s Gurit Holding AG as the sandwich core material.

It applies the material in various thicknesses (10-40 mm) and densities (80-130 kg/m3).

New Zealand epoxy producer Adhesive Technologies Ltd. formulates and supplies its ADR range of resins to Vessev. Jolliffe says this is a system formulated specifically for resin infusion with a low viscosity and long pot life.

“The combination of the materials allows individual laminates to be optimized for strength, stiffness and toughness,” he said. Vessev adds additional reinforcement for global structural loads that allow the platform to be supported on the three foils struts. They supplement that with local support via monolithic reinforcement zones at the connection points of the platform and foil cases.

When foil borne, the structure has a maximum displacement of 4,000 kg for the VS–9. “It needed to be lightweight, yet robust enough for commercial service,” Jolliffe noted. Vessev’s research indicated that a carbon fiber/sandwich construction was the only viable method to provide a payload of suitable capacity for the VS-9 when foiling.

The company –– which was reborn as Vessev in April 2024 after previous iterations (dating back to 2018) as Freight Fish and then Seachange –– constructs the VS–9 using a combination of tooling options. It molds the more complex parts (using a mixture of male and female tooling) with the larger single curvature parts. It fabricates those latter parts on a laminating table with local tools for features aligned on the table during construction to provide details where required.

For maximum durability, the VS–9’s foils can fully retract, enabling the vessel to operate in shallow water while also protecting the foils so the vessel can be transported on a trailer.

Discover Material Selection with Prospector Premium, learn more here!

As regards engineering challenges for the VS-9, Jolliffe noted that outside of the constant focus on weight –– which is the biggest driver for vessel efficiency –– packaging is definitely the next biggest challenge. An example is providing enough space for service runs (which are different for an electric vessel, and more so for electric hydrofoiling vessel than a traditional vessel) throughout the composite structure. At the same time, it’s vital to maintain watertight boundaries and commercially required fire boundaries. This poised a significant challenge that Vessev’s experts had to overcome.

In-house Manufacturing

“We build everything in-house,” Trout said in a July 31 phone interview from New Zealand. Vessev has about 50 employees, including experienced boat builders, designers and engineers with diverse backgrounds.

“With two VS–9s in service, providing a wealth of user feedback, Vessev now is gearing up to move from small-batch production to a more scalable process, he said. This will enhance production efficiencies and lower costs.

Trout explained that Vessev can build its boats in New Zealand and work with various national regulatory bodies worldwide to meet the local requirements –– in 98 percent of the markets. The exception is the United States. A century-old law –– called the Merchant Marine Act of 1920, also known as the Jones Act –– is a U.S. federal law that regulates maritime commerce in the United States. It stipulates that any marine vessel that moves cargo or people for money must have its keel made in the U.S.

With the U.S. being the biggest global boat market by far (bigger than all of Europe combined), Vessev is committed to manufacturing its product in the United States for compliance reasons. Trout says he now has identified four U.S.-based boat builders who he is confident have the ability to manufacture Vessev’s products to the same quality as it does in New Zealand.

He is not ready to identify those firms yet, but notes they are on both coasts and that the company hopes to begin State-side production by the first quarter of 2026. It can continue to build their motors and hydrofoils in New Zealand, but the keels must be laid in the U.S.

“We have sold boats in the U.S. already, and we know they must be Jones Act-compliant.” He says Vessev already has also sold boats in Europe and in the pan-Asia region.

All-electric & Highly Efficient

“There’s a huge push around the world for electric vessels,” Trout said. Hydrofoils allow the current level of infrastructure in the marine space to be effective as a transport medium.

To use an electric motor to power a conventional boat that displaces water, one needs a really big battery, which is very inefficient. With a big battery, you also need bigger charging, so the boat can charge in a reasonable amount of time.

A very good infrastructure of charging outlets already exists in the marine industry, Trout noted. But it could take, say, eight hours or more to charge a big battery using a 50-amp outlet. And then the amount of run-time you get out of that is not great.

In contrast, with a hydrofoil, you’re removing about 90 percent of the drag on the boat when it is up on the foil. It can go faster, while using just a fraction of the energy needed to power other types of boats. And one also can use smaller, lighter batteries, while getting a great range.

The VS–9 has a service speed of 25 knots (29 mph) and a range of 50 nautical miles (57 miles) on one charge.

Vessev is getting all its tooling prepared for serialized production and Trout predicts that by year’s end they can start building boats to fill the orders they have. Conservatively, by the end of 2026 he says they want to be building one boat a month, with the goal of eventually building a few boats a month.

The base price for an open-style VS–9 is US$576,000, while a fully loaded boat (with a totally enclosed cabin, with heating and air conditioning, higher-end upholstery, seating, lights, stereos, etc.) will carry a higher cost, based on each customer’s operational requirements.

“If you’ve ever been on a hydrofoil,” Trout says, “it’s like no other boat on the planet. There’s a ‘wow’ factor.” In addition to being quiet and sustainable, it’s a fast, smooth ride. “The boat also performs a banked or coordinated turn, in contrast to a traditional vessel that performs a flat turn, which will push you to the outside of that turn.”

Vessev, meanwhile, is gearing up to help boat enthusiasts and others fill that niche –– not only with the 9-meter VS–9, but potentially with 12- and 18-meter-long platforms, as well.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.