I’ve done several articles on adhesion promotion and there have been additional ones posted on Knowledge Prospector by Ron Lewarchik, A Guide to Providing the Perfect Coating Adhesion and very recently by Jochum Beetsma, Adhesion on Steel via Covalent Bonding. Normally, you wouldn’t see so many articles on the same topic in a short period of time but there have been 44 inquiries in 10 years on adhesion promoters and I decided that besides highlighting the excellent information by my colleagues, I would go back and look at the subject matter and make a few points.

I’ve done several articles on adhesion promotion and there have been additional ones posted on Knowledge Prospector by Ron Lewarchik, A Guide to Providing the Perfect Coating Adhesion and very recently by Jochum Beetsma, Adhesion on Steel via Covalent Bonding. Normally, you wouldn’t see so many articles on the same topic in a short period of time but there have been 44 inquiries in 10 years on adhesion promoters and I decided that besides highlighting the excellent information by my colleagues, I would go back and look at the subject matter and make a few points.

Most of the time in coatings formulations, you can look at ingredients in their mass effect on the formula and in working with materials repeatedly, see patterns of what happens with increasing or decreasing a particular ingredient. That’s even without setting up experiments and using experimental design. When we’re talking about additives and their effect in small quantities it is easy to look at them and neglect the fact that sometimes it may seem like even with a minor amount, there could be a major impact on the coating performance. Such is true with adhesion promoters, and in my experience is also true with UV absorbers, wetting agents and a few others.

I am not trying to take an easy road to advice but sometimes it’s necessary to step back and understand what your problem is, and what you can do about it. With the five articles on adhesion promotion, the one thing that you will notice is that they approach things from different places and end up with information that is somewhat connected but still separate. What I am going to suggest is that anyone who is contemplating using adhesion promoters spend time looking at what chemical bonds are formed, and the order of addition. Once upon a time one could call up the technical service department at a large company and ask for information. Nowadays more often than not you may end up with possible solutions, but in the case of adhesion promoters using the right amount is as important as getting the right chemical composition, pH and order of addition.

This is where I will make a suggestion for anyone who is looking for an additive as the solution. Yes you can read these articles and that will help you understand some things, but you really need to start with ULTRUS™ Prospector® and use the general search bar as a start (Paint & Coatings Ingredients, Additives, & Binders | Prospector). You might search for adhesion promotion as an example. From there you will get a lot of suggestions which may not appear to be helpful. This is where you need to be patient and see what the companies’ data sheet recommends for a specific system (industry information). There may be case studies, and in some cases it may be necessary to go outside UL. You may end up needing to call the company and speak with someone who we’ll give you suggestions. But remember that adhesion promoters are sensitive to where they are added to a system as well as the amount that is used which requires a ladder study.

Another item that is overlooked is surface preparation. A surface may appear clean but is not. Any contamination on the surface can disrupt good adhesion. Refining the surface increases adhesion in most cases but there have been multiple papers that dispel the phenomenon.

Based on type, the adhesion promoters market can be classified into silane, chlorinated polyolefins, maleic anhydride, titanate & zirconate, and others. Silane is a commonly used type of adhesion promoter due to its excellent chemical properties. These are used for ultrahydrophobic treatments in urethane, epoxy and acrylic systems. Titanates and zirconates are used in surface primers, sealants, industrial coatings, and various other industrial applications. Again an important factor is in the order of addition when an adhesion promoter is added to a system. This is where getting advice from the technical service department of a supplier may be useful and save some time in evaluation. Below is a road map to what is done.

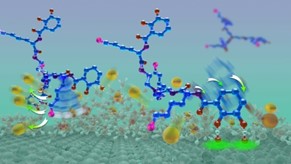

The main general classes of coupling agents are comprised of the silanes and titanates. Most of the organosilanes have one organic substituent and three hydrolyzable substituents. For surface treatment applications, the alkoxy groups of the trialkoxysilanes are hydrolyzed to form silanol containing species. The final result of reacting an organosilane with a substrate ranges from altering the wetting or adhesion characteristics of the substrate, utilizing the substrate to catalyze chemical transformations at the heterogeneous interface, ordering the interfacial region, and modifying its partition characteristics. Titanates act as organometallic chemical bridges between two dissimilar phases such as an inorganic pigment and a polymer binder – or as an adhesion promoter for a coating on a metal substrate. They provide an alternate to silane coupling agents and couple to non-silane reactive substrates such as CaCO3 and carbon black.

Once you get into the habit of thinking about the true science of adhesion, it is redemptive. You don’t have to waste time on surface energy or worry about creating lots of chemical bonds. You just focus on whatever will give you strong entanglement across the interface, always remembering that too much of a good thing is a bad thing – you make matters worse by trying too hard.

If you are going to stick to a metal-oxide surface using, a triethoxysilane (TEOS), focus your efforts on providing a stable oxide that reacts well with the silane and which isn’t too sensitive to whatever environment your product will meet during its use. And make sure that the other end of the adhesion promoter reacts quickly and permanently with the other surface.

The silanes react with both the polymer and the substrate to form covalent bonds across the interface. Silane adhesion promoters are used in urethane, epoxy, acrylic and latex systems. Receptive inorganic surfaces are those that have hydroxyl groups attached to elements such as Si, Al, Ti and Fe. A number of different commercial silane coupling agents are used in coatings with levels that range from 0.05-1.0%. Methacrylic phosphate monomers that improve adhesion to metal, concrete, glass and other inorganic substrates and that can be used in both water- and solventborne formulations are available. There are also acrylic phosphate functional monomers that improve adhesion to various metal substrates. The acrylic reactive group provides a higher reaction rate in UV- and EB-curable applications. Other adhesion promoters that are in the marketplace are titanates (such as isopropyl tris-[N-ethylaminoethylamino] titanate), zircoaluminates, zirconates, aryl/alkyl phosphate esters and proprietary metal organic compounds.

Due to high chemical stability, low price, excellent balance of physical properties, possible recycling, etc., the amount of thermoplastic olefin (TPO) consumed by automotive parts, household electrical appliances and molded general goods businesses is increasing. However, TPO is a material with low surface energy that makes painting and adhesion problematic, hence chlorinated polyolefin (CPO) has found wide use as an adhesion promoter. There are several factors that can affect the performance of a CPO based adhesion promoter.

Resources:

Introduction to Surface Energy | 3M Science of Adhesion Educational Series

AdhesionPromoterGuide_1.pdf.aspx (ppgaerospace.com)

https://holdtight.com/products/holdtight-102

Auto Primers Adhesion Promoter Product Page (rustoleum.com)

Adhesion Promoters | Product Types | Eastman

DOWSIL™ P5200 Adhesion Promoter

Manchem Zircoaluminates | Adhesion Promoter

Understanding Surface Energy: Key to Adhesion Success

What is the impact of surface energy on material properties

Solventborne adhesion promoters for difficult-to-adhere-to substrates

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).