As polymers respond to the challenge of using feedstocks other than fossil fuels, several innovative examples are emerging, especially for the 3D printing industry, which is increasingly calling for resins made with renewable resources to advance more sustainable additive manufacturing.

Plant-based resins

A team from the Universitat Politècnica de Catalunya – BarcelonaTech (UPC) and the Institute of Chemical Research of Catalonia has developed polymeric resins derived from plant-based materials aimed at reducing 3D printing’s reliance on fossil fuel-based resins.

To meet this challenge, researchers at the Universitat Politècnica de Catalunya – BarcelonaTech (UPC) and the Institute of Chemical Research of Catalonia (ICIQ) have developed new 3D polymeric resins from monomers which, to be industrially viable, must be liquid, solvent-free, and feature fast polymerization kinetics.

This research was carried out in two stages: in the first, the polymeric resin was formulated using plant-based materials; in the second, ICIQ printed the resin.

The polymeric resins developed by the UPC and ICIQ team are derived from natural sources – succinic acid, malic acid and tartaric acid – which require only a single synthesis step to be converted into functional resins. Succinic acid is a compound found in foods such as corn and broccoli. These can then be used in digital light processing (DLP) or stereolithography (SLA) printers.

Currently, the IMEM-BRT group is also researching soft biopolymers—such as alginate, chitosan and gelatin – as sustainable superabsorbent materials for applications in soils, batteries and polyelectrolytes for desalination cells.

Discover Material Selection with Prospector Premium, learn more here!

Vitrimers – sustainable, self-repairing and antimicrobial

From medicine to electronics and optics, new materials developed Kaunas University of Technology (KTU) in Lithuania can be applied where cleanliness, precision, and durability are essential. They stand out not only for their functionality but also for their sustainability: they are made from renewable raw materials, and no solvents are used during production.

The materials – polymers developed by KTU researchers – belong to the class of vitrimers, a relatively new type of polymer discovered only about three decades ago, and named vitrimers just 15 years ago. This makes it a rapidly growing research field that is attracting increasing attention from scientists worldwide.

Until now, and according to Professor Jolita Ostrauskaitė at the KTU Department of Polymer Chemistry and Technology, most vitrimers were derived from petroleum resources and required catalysts for processing.

“The polymers we have developed are unique because they are made from plant-based compounds, cured under UV or visible light, and do not require catalysts for processing. This happens naturally due to the chemical structure of the material itself,” emphasises Ostrauskaitė.

“Vitrimers are thermosetting polymers that, thanks to dynamic covalent bonds, can be thermally reprocessed or reshaped, similar to thermoplastics. At certain temperatures, they can self-heal after damage and also retain a temporary shape that can later be restored – this is known as thermally responsive shape memory.”

This is important not only because it simplifies the technological process but also for sustainability – catalysts are often expensive, derived from non-renewable resources, or even toxic. By eliminating them, material consumption is reduced, no additional additives are needed, and the technology becomes simpler, safer, and more environmentally friendly.

“The starting compounds used in the study were obtained from plant oils and by-products of biodiesel production; certain fragments interfere with bacteria and other microorganisms, disrupting their vital functions. This is why such materials can be used to create surfaces or products that must remain clean and hygienic, for example, in medical devices, electronics, sensors, or other items where microbial control is critical,” explains Ostrauskaitė.

Optical 3D printing

One of the most notable achievements by KTU researchers is the polymers’ suitability for optical 3D printing, which can be performed at room temperature, consumes less energy, and generates less waste.

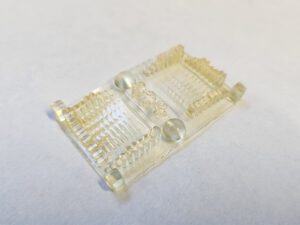

When exposed to UV or visible light, these polymers can be printed in complex shapes, such as medical device connectors. “We successfully printed a Y-shaped connector – a typical medical component used to join tubes in infusion or respiratory equipment. This part requires high precision, making it an excellent test of the material we developed,” says Ostrauskaitė.

Optical 3D printing technology allows the production of other complex components, such as optical lenses or electronics parts, which demand extremely precise dimensions and geometry. Additionally, the material can be shaped into temporary structures that can later be transformed or repaired – invaluable for prototyping and quickly responding to industrial needs. A related feature is the polymers’ antimicrobial properties, arising from structural fragments in their composition.

Perhaps the most significant scientific achievement was combining, in a single material, plant-based origin, radiation-induced polymerisation, self-repairing ability, shape memory, antimicrobial effect, and suitability for optical 3D printing. Such multifunctional and sustainable solutions are still very rare, making this an important step forward both scientifically and industrially.

References

Synthesis of bio-sourced liquid resins and their photopolymerization with poly(ethylene glycol) diacrylate in the roadmap to more sustainable digital light processing technologies.

RSC Appl. Polym., 2024, 2, 284–295, DOI: 10.1039/d3lp00207a

Antimicrobial Vitrimers Synthesized from Dipentaerythritol Pentaacrylate and 2-Hydroxy-3-phenoxypropyl Acrylate for LCD 3D Printing.

https://en.ktu.edu/news/new-generation-polymers-developed-by-ktu-scientists-sustainable-self-repairing-and-antimicrobial/

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.