Sustainability is driving innovation and shifts in the paradigms of coatings formulation, manufacturing and utilization. However, sustainability can be broad in scope and poorly defined. One accepted strategy is to use the seventeen United Nations Sustainable Goals (UN SDG) as guidelines. Each organization has to define what sustainability means to them and how to make meaningful contributions to these sustainability goals. No single industry, individual manufacturer or business can make contributions to every SDG. Making informed decisions as to which goals are attainable by your organization is essential.

The seventeen UN Sustainable Development Goals (SDG) and how do they apply to coatings?

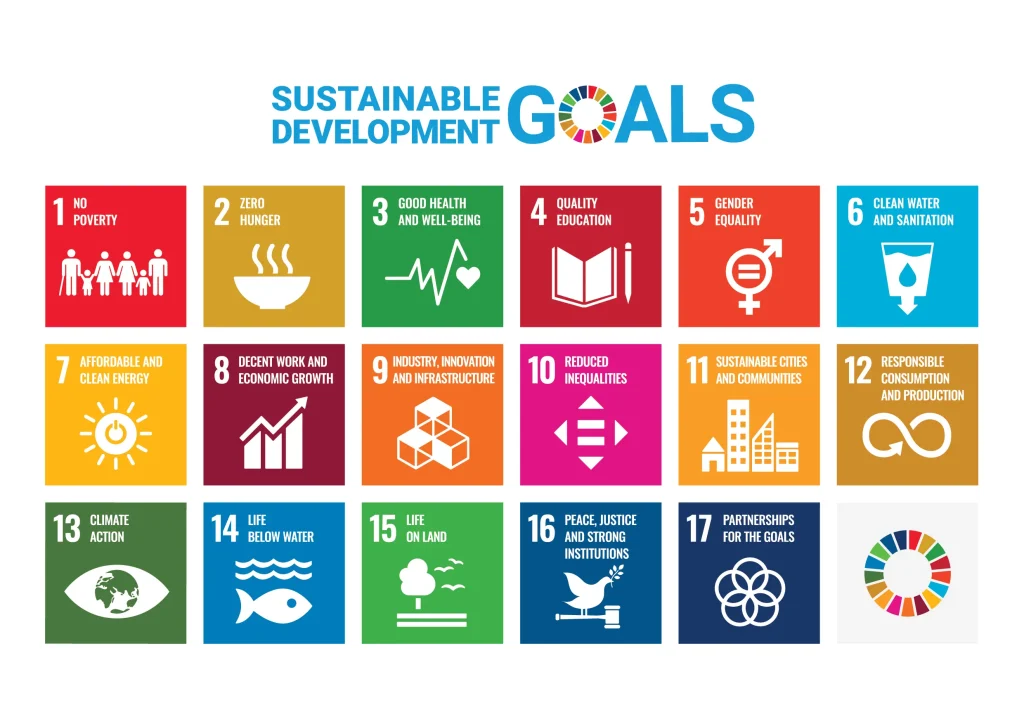

The seventeen UN Sustainable Development Goals are shown in the graphic below. Not all of them have readily apparent connections to coatings, but some are easily linked. Coatings can contribute to Goal 3, Good Health and Well-being for example by helping to maintain clean living and working spaces. Maintenance and protective coatings contribute to Clean Water and Sanitation projects as well as clean energy facilities. By prolonging the life of infrastructure and helping conserve energy, protective and heat reflective coatings help facilitate Sustainable Cities and Communities. Let’s look at the ways determining a products carbon footprint can contribute to sustainability.

Where/how does PCF fit into the UN SDG?

When we consider PCF within the framework of the UN SDG, what specific goals are addressed? Goal number 13, Climate Action comes first to mind, but I think that two other goals also apply. Responsible consumption and production (SDG 12) encourages the use of raw materials and production processes that minimize negative impact to the environment. For purposes of calculating the PCF, that negative environmental effect is emission of greenhouse gases expressed as Kg of CO2 equivalents. Goal 17 addresses partnerships that help achieve any of the other UN SDGs, and an accurate assessment of PCF is only possible by partnering with other organizations such raw material suppliers.

What is the timespan of your products PCF?

What is a products carbon footprint or PCF? Why is it of interest? Is my company required to determine the PCF of our products? There is also confusion about what PCF measures. Life Cycle Analysis/Assessment (LCA) is not the same as the PCF, but there are common parameters. PCF is only concerned with climate impact measured as Kg of CO2 equivalents while LCA measures the total environmental impact of a product. We also need to define the portion of a products lifespan we are assessing. For example, Cradle to Grave equals the total PCF from first raw material production through the end of the products useful life. The more meaningful measure for a paint manufacturer is Cradle to Gate. This equals the total PCF starting with the raw materials incorporated into your process and all GHG generated until the product leaves your facility. This can be broken down into three scopes.

Scope 1 emissions: direct emissions from manufacturing processes. GHG generated from chemical reactions or evaporation during processing, not necessarily CO2 but expressed as the equivalent amount of CO2.

Scope 2 emissions from direct energy used during manufacturing.

Scope 3 emissions: embodied GHG emissions contained in raw materials used in manufacturing including extraction, processing and transportation.

Methods to determine PCF:

DIY Solutions are the least costly but require the most commitment from your organization. Like any home grown solution the learning curve can be steep but satisfying. The USEPA offers a Simplified GHG Emissions Calculator as a downloadable Microsoft Excel spreadsheet which can be used to calculate a PCF for a product. The next method of calculating PCF is to purchase dedicated software. There are numerous vendors offering software to calculate PCF from input data. Some applications even utilize AI modules to data mine the Scope 3 PCF information of your input raw materials to aid in the calculation of your products final PCF. Hiring a consulting firm is probably the most expensive solution but may be the best choice if the most accurate assessment is required. Specialized consultants will work with your formulation, raw material sourcing, manufacturing and distribution personnel to calculate the PCF for your products.

Work smarter and win more, with powerful software to manage regulatory, supply chain and sustainability challenges, learn more about ULTRUS here!

What to do with it once you have determined your PCF?

PCF may need to be reported for regulatory purposes as is often required for pollutant emissions. Customers, including manufacturers, contractors or architects, may be interested in the PCF of the paints they buy. This information can be used to calculate their own carbon footprint or that for a particular project. PCF information can help establish a baseline for corporate carbon footprint reduction if your organization tracks this information. Knowing the PDF of your products is essential if your organization wants to investigate areas where your PCF can be reduced.

Some Ways to Reduce PCF

Scope 1 Emissions – direct emissions from operations:

- Alternate chemical reactions/processes with lower direct emissions

- Emissions recovery and reuse, solvents or waste gases

- Carbon capture can generate raw materials from emissions

- Participate in paint recycling programs such as PaintCare® and encourage your customers to participate as well

Scope 2 emissions – from energy purchases:

- Energy efficiency, reduces energy use and emission while saving money, the cleanest energy is the energy you don’t use

- Use renewable energy sources

- Purchase carbon offsets from certified, reputable sources

Scope 3 emissions – from upstream sources

- Raw materials with lower PCF – biobased, carbon capture, or recycled feedstocks

- Purchase materials from local/regional sources to reduce emissions from transportation

- Use rail transportation over truck deliveries emit less CO2 per mile

- Bulk purchases are delivered more efficiently than totes or drums

- Use recycled materials where possible such as in product packaging

Knowing the PCF of your organization’s products is an important step on the road to sustainability and climate action. While it seems like a daunting task, concentrating on one step at a time makes it possible.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.