Fashion textiles are usually soft, comfortable to wear, and the fabric falls loosely. But the situation is different in the case of technical textiles. These have to meet different requirements. Compression bandages, for example, should put pressure on human tissue, therefore the stretchability of the material has to be right. Materials for protective jackets need to have a certain bending stiffness: if something hits them, the material should protect the wearer and not yield. Textiles for car seats have to be durable, especially at the edges. Manufacturers of these products have two determining factors with which they can define the properties: the yarns, as well as the structure via which the individual yarns are interconnected – such as special weave patterns or mesh variations.

The mechanical properties of the yarns can be identified relatively easily: with a device into which they are clamped. It pulls the fiber and measures how much force is required to stretch it by a predetermined value. It is harder to assess the properties of the fabric: it has to be produced and then tested. However, this can usually only be done with samples, as it would be too costly to produce all conceivable designs with the various yarns.

Looking for materials to improve the structure of your textiles?

Prospector has thousands of material listings from global suppliers. Find technical data, order samples and more now.

Get Material Data

Integrated simulation

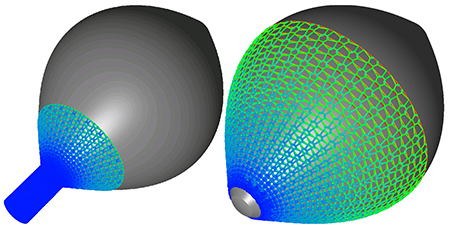

Now, the Fraunhofer Institute for Industrial Mathematics ITWM in Kaiserslautern, Germany has developed a simpler method to improve the properties of textiles. “We simulate the behavior of the materials,” says scientist Dr. Julia Orlik. “In this way, we are able to accurately predict which properties the fabrics have, depending on the yarn and structure.”

With simulation, the researchers can examine all of the conceivable variants of patterns and yarns and analyze which one is optimal for the desired application. And for the first time, they can simulate the contact between the yarns, examining how well the individual threads slide over each other. And how this in turn affects the entire fabric.

A starting point for the simulation are the parameters provided by the manufacturers, which relate mainly to the yarns. In terms of contact properties, it is more difficult: few manufacturers can determine these parameters. Therefore, the researchers take measurements from selected real pieces of fabric, comparing them to the simulations and adjusting the parameters until the results of the simulation and the experiment match.

The researchers not only analyze individually selected structures, they also change them gradually. “Take the shape of a a single mesh, for example,” says Orlik. “It resembles a Greek letter omega (Ω). Now, you can make this Ω longer and narrower, or shorter and wider. We change the mesh shape continuously and see what effect that has on the entire fabric.”

In addition, the researchers are investigating the yarns – how the properties of the fabric change if, say, a more stretchable yarn is used. The parameters are provided by the manufacturers. If a manufacturer has already decided upon a certain yarn, the researchers look to identify the best structure for this yarn.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Leave a Reply or Comment