To address a fast-evolving consumer landscape, DSM has been developing resins for self-matting floor coatings – specifically, its Decovery® SP-2022 XP resin. This resin enables superior aesthetic and functional performance, improve production efficiency, and ensures a lower environmental impact.

To address a fast-evolving consumer landscape, DSM has been developing resins for self-matting floor coatings – specifically, its Decovery® SP-2022 XP resin. This resin enables superior aesthetic and functional performance, improve production efficiency, and ensures a lower environmental impact.

Trends and developments in floor coatings

Over the past few years, consumers around the world, and across a wide range of markets, have been progressively drawn to low-gloss and matt finishes, believing these finishes can deliver a chic, modern-feel aesthetic. In the floor coatings market, in particular, there has been a growing demand for ultra-matt coatings that both protect and beautify the natural qualities of wooden and seamless flooring substrates.

Nevertheless, until recently, many commercially available matt floor coatings have been coming up short on functional performance while having a high environmental impact, as well as being difficult to process and requiring labor-intensive formulation. In particular, floor coaters using commercially available matt solutions would typically experience a range of problems, including overlap marks and polishing issues, while end users would have to manage low stain and scratch resistance.

The research and development journey

To address the strong market demand for a resin that would enable superior ultra-matt floor coatings, DSM wanted to deliver an innovative product and open a new horizon in self-matting coatings. By undertaking a deep field research into the precise demands of the floor coatings market, participating in a range of specialized flooring market conferences and listening closely to floor coating applicators, DSM was able to identify the exact qualities and performance parameters the new matting resin product would need to integrate.

In 2016, a multidisciplinary team within DSM Resins & Functional Materials began developing a self-matting coating resin for wood and seamless flooring that would make formulations quicker and easier, while also outperforming conventional coatings on the functional, aesthetic and environmental performance. In order to optimize the development process, DSM kept market demands top of mind at all times, and involved customers and floor coating applicators in the testing of the self-matting resin prototypes. The final SP-2022 XP resin was launched in March 2019, and – so far – is meeting the needs of stakeholders across the value chain.

Enabling new possibilities for formulators

Above all, the unique proprietary technology behind the Decovery® SP-2022 XP resin facilitates coating systems that are quick and easy to formulate, driving the practicality of the overall coating process. In particular, the self-matting Decovery® SP-2022 XP resin enables coating formulations without supplementary matting agents and additional process steps. This leads to fewer operational and formulating mistakes, as well as up to one-hour time savings in operations compared to other commercial alternatives.

With the coatings market increasingly looking for solutions that are easier to process and manage, the Decovery® SP-2022 XP resin provides answers to many of the key functional challenges of the coatings industry. For example, the chemical technology behind Decovery® SP-2022 XP means that the product remains highly stable within cans, ensuring that coating manufacturers can enjoy good product reliability at all times.

Supporting the challenges of applicators

While the coating formulators are key stakeholders in the overall coating process, ultimately it is the end performance and usability of the product that will enable consumer demand and drive market uptake. The avoidance of matting agents enabled by Decovery® SP-2022 XP delivers key benefits here too. In particular, the qualities of this resin ensure that the lowest gloss lacquer available leaves no roller or lapping marks, helps avoid polishing issues, and enables spot repairs, unlike many of the commercially available alternatives.

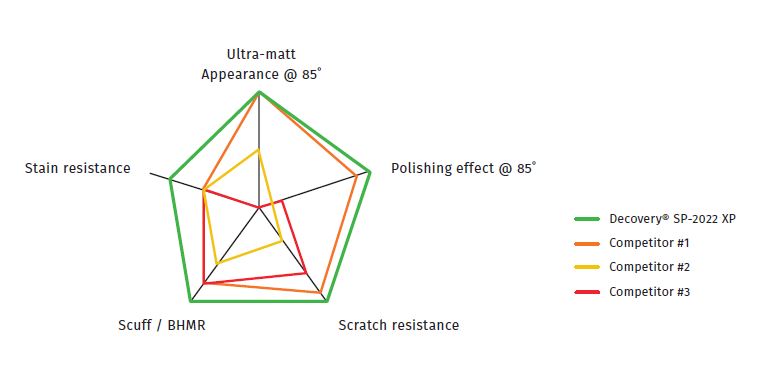

Moreover, Decovery® SP-2022 XP is chemical- and stain-resistant, as tested to DIN 68861 part 1B, which demonstrates good removal after testing of coffee, water, tea, ethanol, and cleaning agents. Decovery® SP-2022 XP also offers mechanical- and scratch-resistance, excelling in taber shear and scratch performance tests with forces greater than 2N, as well as Black Heel Resistance Mark tests. These showed that sustainable alternatives with low carbon footprints can compete functionally with more conventional, less sustainable coating resins for the floor market.

Leveraging sustainable technology

What’s more, to drive the sustainability value of its self-matting resin, DSM decided to leverage the technology of its Decovery® platform. This family of paint resins for indoor and outdoor applications contains nearly 50% plant-based content, enabling a carbon footprint reduction of up to 34% compared to alternative coating systems.

As a result, DSM’s Decovery® SP-2022 XP resin is environmentally friendly, containing 30% bio-based content, and is low in VOCs (less than 5%) and odor. This makes it a healthier and more sustainable alternative to many of the commercially available coating resins around the world. The resin is compliant with Ecolabel, Nordic Swan, The Blue Angel (Der Blaue Engel), and AgBB labeling, keeping floor coating formulations aligned with – and in some cases ahead of – the demands of regulatory authorities.

A future of self-matting products

DSM believes that, thanks to the research and development process that led to Decovery® SP-2022 XP, it will continue developing ultra-matt floor coatings in the future. These solutions will be more sustainable and offer consumers higher product performance. Going forward, DSM will continue to close customer feedback loops to make this resin better and better, in order to meet the performance requirements of real-life applications.

Indeed, in the years ahead, it is likely that DSM will look to broaden the scope of this self-matting resin to other application areas, such as walls and construction, as well as try to further increase the resin’s bio-based content. Ultimately, the whole of the coatings industry will need to develop technical solutions that not only address market trends, but also enable more sustainable living.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.