SABIC Specialties Business

Get in Contact with SABIC Specialties

KEY MARKETS & APPLICATIONS

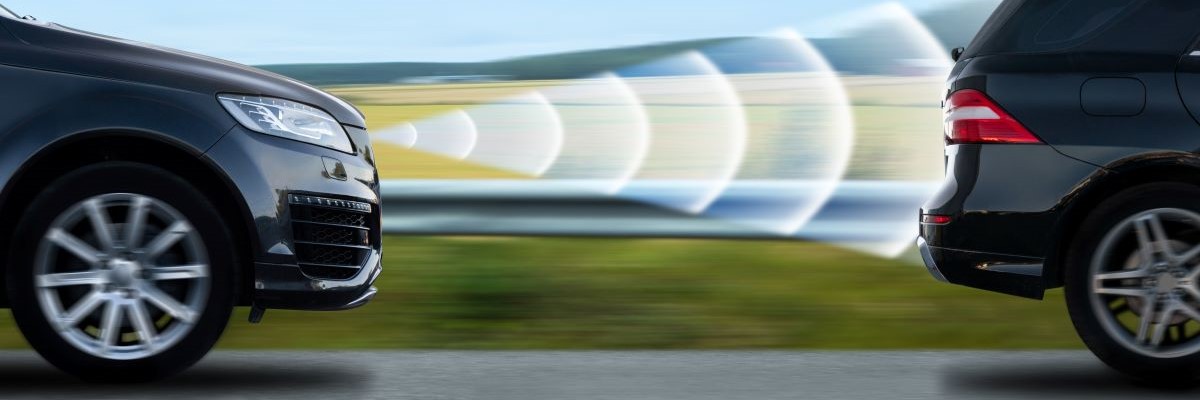

Near IR transparent thermoplastics EXTEM™ resins (polyimide) and ULTEM™ resins (polyetherimide) have multiple benefits over glass and thermosets including easier design, simpler assembly, and larger builds...Learn more

ULTEM HU1004 resin offers medical device industry a single material solution. It withstands rigorous sterilization processes - steam sterilization at 134°C, gamma irradiation, hydrogen peroxide sterilization with/without plasma...Learn more

SABIC’s Specialties Business products can enable the Hydrogen revolution all the way from the energy production, conversion of hydrogen, to final use such as in fuel cells, electrolyzers and its infrastructure...Learn more

FEATURED PRODUCTS

SILTEM™ Resin STM1500

Non-halogenated flexible SILTEM™ resin series, polyetherimide + siloxane. Easy to extrude amorphous copolymers. No intentionally added PFAS. Excellent high-heat performance, processability, durability. For potential use in wire & cable jacketing & tubing.

LNP™ ELCRES™ CRX7416U

LNP™ ELCRES™ CRX7416U copolymer resin is a custom-colorable, injection molding grade providing UL94 V0 compliance at 1.0 mm and very high flow properties potentially enabling designs with thinner walls and complex geometries.

EXTEM™ Resin RH1016UCL

EXTEM™ RH1016UCL resin is a near infrared transparent, amorphous polyimide. Maintains dimensional stability for mounting parts in PCB assembly with reflow soldering (245-260°C). Edison Award Gold Winner 2023.

LATEST NEW PRODUCT LAUNCHES

INDUSTRY SOLUTIONS: METAL REPLACEMENT & MORE

Electric Vehicles

Replacing metals and other materials with advanced thermoplastics can help optimize EV batteries EVSE by reducing weight, expanding design freedom.

Consumer Electronics

Designing with metal for consumer electronics can result in high costs and long production cycles. ULTEM™ resin provides a lower cost solution with comparable performance.

Medical Devices

Improve medical device durability and sustainability. In the post-COVID world, there is a renewed focus on proper selection of plastics to address infection control challenges.

SUSTAINABILITY

LNP™ ELCRIN™ iQ Resin for Circular Solutions

A proprietary technology which uses chemical de-polymerization to process single used recycled PET plastics into a polymer – polybutylene terephthalate (PBT). Contains up to 60% recycled weight content.

ISCC+ Certified Renewable Bio-Based ULTEM™ Resins (Polyetherimide)

Deliver a lower carbon footprint while offering exactly the same high performance and processability as incumbent ULTEM materials. First certified renewable high temperature, amorphous resins available.

New PCR-Based NORYL™ Resin Technology, Polyphenylene Ether (PPE)

Using 25% or more post-consumer recycled content. Can be incorporated into over 200 existing grades, as well as unlimited number of new grades based on customer requirements.