Funded by the BMWK (German Federal Ministry for Economic Affairs and Climate Action), the research project “Tape Technology Transfer Hub” (T³-Hub) has been running since December 2021, led by the Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University, together with five other consortium partners.

Because of their high potential for producing composite parts with increased stiffness and strength, thermoplastic composite materials, such as unidirectional (UD) tapes and composite sheet, are increasingly being used in aerospace and the automotive industries. UD tapes are also being increasingly used in cost-conscious and high-volume industries to reduce material consumption, costs and CO2 emissions.

Local reinforcement of an injection-moulded component through a small quantity of UD tape can be utilised to reduce wall thicknesses and save material. However, the use of a small quantity of thin UD tapes to increase the properties of an injection-moulded part has not yet become established.

In an earlier study, a research project carried out a detailed analysis of the use of UD tapes in injection-moulded components. The aim was to identify potential applications and to extend the range of use beyond the high-performance application, especially in areas in which cost reduction is the principal objective.

The T³-Hub project is exploring how tape technology for conventional injection-moulded parts can be transferred to large-scale production, in order to be able to optimally exploit the cost-saving effects. The highly promising results were presented at the 32nd International Colloquium Plastics Technology in Aachen in February 2024.

Within this project, methodologies for evaluating the potential and for the re-design of components are being developed. The entire value-added chain is being explored, including tape production, insert production and back-moulding. In parallel with the practical implementation and investigation, a complete data chain is being built up and the process simulated.

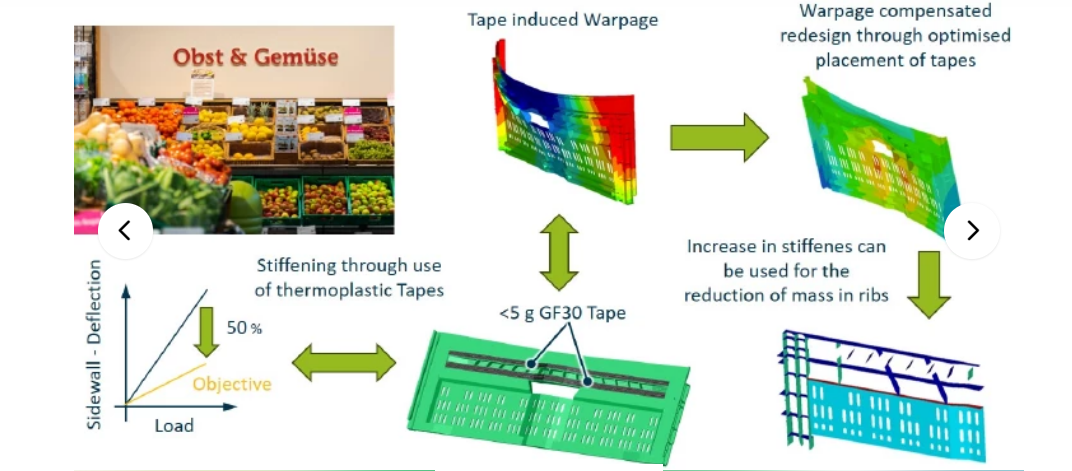

IKV has developed an optimisation methodology for using local tape inserts in redesigned injection-moulded parts, based on the particular load case. In injection moulding, the considerable differences in stiffness and thermal expansion coefficients between the tapes and the compound often lead to significant warpage. As part of this project, IKV developed an optimisation algorithm that enables such components to be automatically redesigned without the process leading to warpage. The approach is to utilise the induced warpage in the tape structure to balance out the warpage in the other tapes (Fig 1).

IKV’s optimisation algorithm has been used successfully to redesign the side wall of a reusable folding box, of a type used worldwide in the logistics industry; it is estimated that over 20 million are in circulation. The aim is to increase flexural rigidity by 50%, while minimising warpage. This target was reached for two different thermal load cases, and the warpage in both cases was within specifications. To achieve this target, 4g of a PP-GF30 tape was sufficient, representing around 1% of the total weight of the component.

The next step is to validate the simulation results by integrating the optimised tape structures into the production process. Subsequently, the IKV algorithm will be used to optimise the amount of compound needed to produce the boxes, making it possible to use the process without extensive knowhow.

Discover Prospector Premium, learn more here!

UD tapes made of carbon or glass fibre with thermoplastic matrix systems offer a very high level of lightweight construction potential. A wide range of applications are conceivable employing local reinforcement in injection moulded plastic parts, hybrid metal components or pure FRP components, achieved through tape laying or tape winding. The UD tape determines the component quality and the cost-efficiency of the process to a decisive extent through its properties such as tolerances, homogeneity and the degree of fibre impregnation. On the new unit, the interactions that result between tape quality and the selected method of further processing, (eg tape laying, tape winding or injection moulding, are being tried out and assessed).

The tape unit can be used to produce UD tapes with a tape width of 25 to 75mm and a tape thickness of 0.1 to 0.3mm, employing a production speed ranging from 0.6 to 10m/min. It is possible to process glass fibres (> 2400 tex) and carbon fibres (> 24K) using polypropylene (PP) or polyamide (PA) as the matrix. An optical quality assurance system captures fibre spreading as well as gaps and overlaps. It also conducts continuous measurements to determine the tape width and tape thickness.

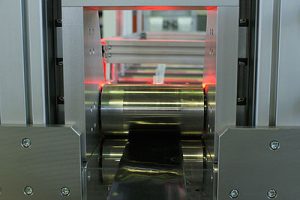

At present, producing UD tapes still is expensive. For tape technology to be established in mass application, the production process must be resource-efficient and cost-effective. IKV has built a new facility on a pilot-plant scale for the efficient production of tapes by the melt impregnation process. The aim is to be able to raise the production speed to 20m/min. The impregnation tool used for this was developed and designed at IKV from scratch (Fig 2).

A wide variety of material combinations is being processed, because the choice of materials also has a direct influence on the cost and the CO2 footprint. During the process, production data are recorded and correlated with the resultant tape quality. It is then possible to explore, in the subsequent process chain, the tape quality that is needed to obtain optimum results after processing (tape-laying, heating, forming and backmoulding).

The injection moulding process is being developed and demonstrated at the premises of project partner AZL. IKV has since obtained the first results at component level, enabling an understanding of the influence of injection moulding parameters and tape positions on the warpage and positioning properties of the tapes.

Captions

1 Optimisation of the tape positioning for minimising warpage

2 Impregnation tool in the IKV FRP pilot plant for producing UD tapes | Photo: IKV

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.