The topic is hydroxy acrylic resins, which is the general term for several different types of resins and methods to cross-link them. For the most part, I will assume that it was meant to be focused more on resins that are supplied in water and solvents as a 2-component (Non isocyanate) NISO system, but also could be a 2-component resin system that can be cross-linked that would conventionally contain an isocyanate cross-linker.

The topic is hydroxy acrylic resins, which is the general term for several different types of resins and methods to cross-link them. For the most part, I will assume that it was meant to be focused more on resins that are supplied in water and solvents as a 2-component (Non isocyanate) NISO system, but also could be a 2-component resin system that can be cross-linked that would conventionally contain an isocyanate cross-linker.

Hydroxyl functional acrylic resins are a type of acrylic resin that has hydroxyl groups on its molecular structure. These hydroxyl groups make it water-soluble and compatible with a variety of other materials, making it a versatile resin with many applications in industrial and automotive coatings. It can also be supplied as a solvent compatible system.

In industrial coatings, hydroxyl functional acrylic resins are used in primers, topcoats, and corrosion protection coatings. They provide excellent adhesion to a variety of surfaces, making it a good choice for these applications. Hydroxyl functional acrylic resin is also resistant to weathering, chemicals, and abrasion as well as resistant to chipping, scratching, and fading, making it a good choice for topcoats and clear coats.

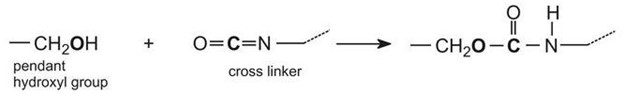

Non-NISO resins are easiest to explain by functionality. Reactive groups contain hydroxy functions which can react with isocyanates or melamines. Some contain glycidyl functions (epoxy group) that will react with amines and carboxylic acids. These groups allow bonding between polymer chains to form a stronger polymeric material. Because they are functional in almost all cases the reacted polymer would have superior properties to non functional, non crosslinked. In almost all cases these are industrial resins due to cost and functionality.

They influence resin properties, applications, and final properties of the film/coating obtained. -OH functionalization and the presence of carboxyl groups can improve the adhesion on a substrate. A large number of carboxyl groups will also help to solubilize the resin in water. To get a resin with specific properties or to reduce its cost, different monomers can be incorporated into the acrylic polymer. Several resins are highlighted in this article; (does not imply or infer a preference. As example) the first being Hypomer MT-2550K[1]. It is an Elementis hydroxy acrylic matting resin for non aqueous industrial and automotive coating systems. Another group of hydroxy functional acrylic resin is offered by Dianal. There are three series of varying hydroxyl levels[2]. A last one is Synaqua® E21219, a waterborne NISO (Non isocyanate) from Arkema[3]

Work smarter and win more, with powerful software to manage regulatory, supply chain and sustainability challenges, learn more about ULTRUS here!

Acrylic resins can be accessible as self-crosslinking versions (rather solvent-based or water-based). Some -R groups in the copolymer structure are blocked amide (alkoxymethyl acrylamides) groups. For example, N,N-bis-butoxy-methylamide. During the curing process, they bond with the hydroxyl groups available on the copolymers leading to a cross-linked network. The curing is an oven-bake at elevated temperatures.

Compared to resins, crosslinked resins with curing agents, self-crosslinked resins have:

- chemical resistance

- increased hardness

- higher gloss

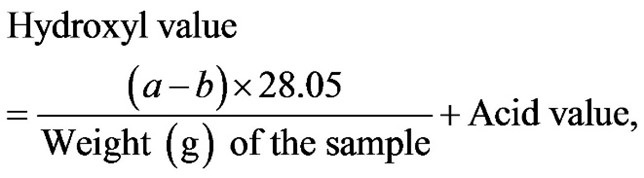

The hydroxyl value is an indicator of the reactivity of the acrylic resins functionalized with hydroxyl functions (i.e., the number of OH groups available). It is usually expressed as the KOH mass in mg equivalent to the amount of acetic acid reacting during the acetylation of 1g of resin. The higher the hydroxyl value, the higher the reactivity (and thus the cross-linking possibilities).

The hydroxyl value can be calculated using the following equation. A chemical substance may also have a measurable acid value affecting the measured endpoint of the titration. The acid value (AV) of the substance, determined in a separate experiment, enters into the equation as an adjustment factor in the calculation of the hydroxyl value:

HV=56.1×N×(VB−Vacet)Wacet+AV

where a and b are the volumes (mL) of ethanolic KOH consumed in the blank determination and in the titration of the sample, respectively.

The acid number is an indicator of the number of carboxyl groups present in the copolymer. It is usually expressed as the amount of KOH needed to neutralize 1g of resin (See DIN 53402 or ISO 2114). The number of carboxyl groups has an impact on the adhesion properties of the resin and the solubility in water. The higher the acid value, the higher the number of carboxyl groups.

New generation of more sustainable 2K systems: Lower carbon footprint 2K NISO systems can be bio-attributed through the mass balance approach, and further development is ongoing with waterborne 2K NISO systems.

[1] ELEMENTIS_HYPOMER_MT_2550K_LEAFLET.pdf

[2] Hydroxyl Functional Resin TDS.doc

[3] Innovative Acrylic Polyol Emulsion for NISO paint system | Arkema Coating resins

Other Resources:

- PROSPERSE™ 200 Hydroxyl Acrylic | Dow Inc.

- JONCRYL® 500 by BASF Dispersions & Resins – Paint & Coatings

- Hydroxyl Acrylic Resins – PRP Resins

- Research on Properties of Silicone-Modified Epoxy Resin and 3D Printing Materials | ACS Omega

- SYNOCURE® 892 BA 70 | Arkema Coating resins

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).