by Ronald Lewarchik and Vishakha Makode

by Ronald Lewarchik and Vishakha Makode

In our 2019 article, The Rapidly Growing Segment of Direct-to-Metal Coatings, we highlighted the promise of Direct-to-Metal (DTM) coatings as a simplified, cost-effective, and time-efficient alternative to conventional multi-coat systems. As of 2025, the DTM segment has matured significantly driven by advancements in polymer architecture, additive technologies, and application science. DTM technology is particularly well suited for architectural and industrial applications. This update provides a comprehensive overview of the sector’s evolution, including new formulation strategies, enhanced performance standards, and compliance with increasingly stringent environmental regulations. DTM coatings have now solidified their position as high-performance solutions capable of delivering robust corrosion protection, UV resistance, and surface durability—making them a viable and scalable choice for demanding industrial and architectural applications.

DTM- The One-Coat Revolution

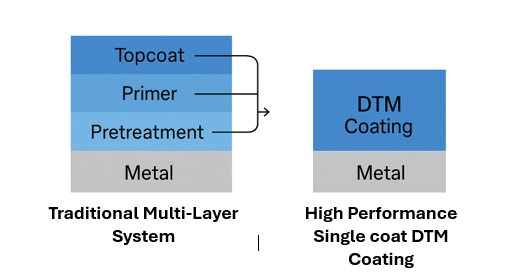

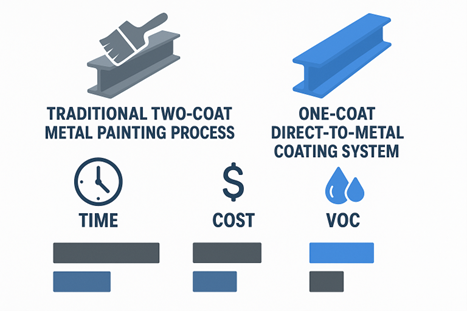

DTM coatings continue to offer a single-layer solution, eliminating the need for separate primers and topcoats. The convenience of applying one coat directly on metal substrates remains a compelling advantage. However more recent DTMs now deliver enhanced corrosion protection, UV durability, and cosmetic appeal previously associated only with multi-layer systems.

Advancements in polymer science, additive engineering, and formulation strategies have enabled DTMs to perform reliably in medium-duty industrial and architectural applications. The industry’s shift toward high-solids and waterborne chemistries, driven by environmental regulations, has not only reduced VOC content but also unlocked new levels of application flexibility and performance.

Accelerate your ESG management and performance no matter where you are on your journey, learn more about here!

Polymer Chemistry: The Core of Innovation

Resin chemistry lies at the heart of recent DTM innovations. New binder technology offers a wide range of curing mechanisms:

- 1K Thermoplastics for ease of application in low-demand environments.

- 1K Self-Crosslinking Systems using ambient-curable acrylics, alkyds, and hybrid latexes.

- 2K Epoxy and Polyurethane Systems offering robust chemical and mechanical resistance

- Moisture-Cure and UV/EB-Cure Systems delivering high-performance, instant-drying options for rapid production.

These DTM chemistries are often integrated into hybrid architectures (e.g., acrylic-epoxy, acrylic-fluoropolymer, or polyaspartic-based systems) that combine the benefits of flexibility, weather resistance, and corrosion control in a single film.

Additives and Formulation Strategy

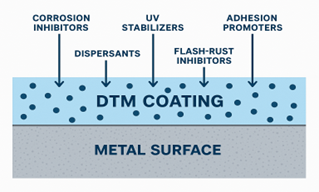

Newer DTM coatings often utilize additives that play a crucial role in bridging the performance gap between traditional systems and single-layer DTMs:

- Advanced corrosion inhibitors like zinc phosphate, magnesium silicates, and organic complexes.

- Flash-rust inhibitors (such as Flash Rust Inhibitors list) tailored for waterborne systems.

- Multifunctional dispersants and surfactants that enhance pigment stability while contributing to rust inhibition.

- Smart rheology modifiers that allow thick films with excellent flow and leveling, crucial for one-coat application.

- Adhesion promoters can either be built into polymers or utilized as separate additives to ensure compatibility with multiple metal substrates.

- UV stabilizers to resist chalking and color fade for exterior durability.

Figure 2: Cross-Section Diagram of DTM Coating on Metal with Labeled Additive Functions

These ingredients are carefully balanced using digital formulation tools and physical mechanical testing to ensure that each component supports long-term durability without compromising storage stability, as well as aesthetics or application properties.

Performance Breakthroughs: Matching or Exceeding Multi-Coat Systems

The new generation of DTM coatings rival two-coat systems for many performance parameters such as:

- Corrosion Resistance: Waterborne acrylics as well as hybrid systems that provide >500 hours of salt spray resistance with minimal scribe creep.

- Mechanical Strength: Crosslinked polyurethanes and epoxy hybrids deliver impact and abrasion resistance suitable for structural steel, machinery, and handrails.

- Weatherability: Acrylic-fluoropolymer blends and silicone hybrids offer unmatched gloss retention and UV durability.

- Application Efficiency: One-pass, high-build films (>75 microns dry) can now be applied with minimal sag or defects.

Moreover, these coatings are increasingly formulated to perform well over surfaces with minimal surface preparation, making them ideal for field maintenance and quick-turnaround projects.

Achieve regulatory compliance, supply chain transparency and meet your sustainability initiatives with WERCS Studio software, learn more about here!

Regulatory Alignment and Sustainability

Sustainability is no longer optional. DTM coatings are now aligned with global environmental and safety standards:

- Low to Zero VOC: Many products meet <50 g/L thresholds, eliminating co-solvents and exempt VOCs.

- Heavy Metal-Free: Modern DTMs have phased out lead, chromate, and cobalt-based compounds.

- Bio-Based Additives: Soy-derived alkyds and renewable polyols are making inroads, enhancing both performance and environmental profiles.

- PFAS-Free Surfactants: The industry is phasing out fluorosurfactants to eliminate persistent chemicals.

Life cycle assessments also show that fewer recoats, and simplified application translate to a lower carbon footprint, making DTMs attractive in green building certifications and sustainable manufacturing practices.

Innovation Outlook: What does the future hold for DTM Coatings?

As Direct-to-Metal technologies continue to mature, their innovation curve is not merely an extension of existing capabilities, but a leap into smarter, more integrated coating systems that

merge material science with digital intelligence and sustainability goals. Looking ahead, DTMs will continue evolving through:

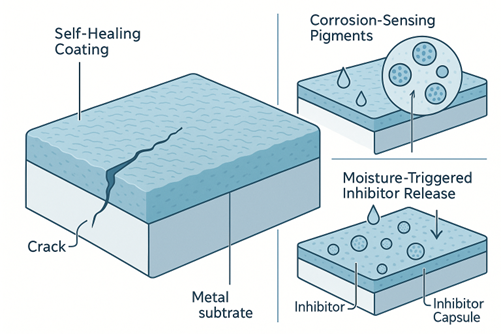

- Smart Coatings: Self-healing microcapsules, pH-responsive corrosion inhibitors, and thermochromic pigments that provide visual cues for degradation or temperature thresholds.

- Nanostructured Binders: Core-shell particles, interpenetrating networks, and dendritic polymers offer better packing density, improved barrier properties, and high crosslinking efficiency without excessive viscosity.

- AI-Assisted Formulation: Machine learning models trained on experimental data can now predict corrosion resistance, gloss retention, and cure time, dramatically accelerating product development.

- Integration with Pretreatment Technologies: Silane-based conversion coatings or phosphate-free prewashes that complement DTMs to form high-performance duplex systems.

- Application Agility: Innovations in thick-film brushable DTMs and aerosol-packaged DTM solutions for field touch-ups and consumer DIY markets.

- High-Throughput Screening: Robotic testing setups and digital formulation libraries enable rapid assessment of thousands of formulations, identifying optimal combinations in record time.

- Bio-Based and Circular Materials: The adoption of resins made from algae oils, lignin derivatives, and recyclable thermosets are emerging, bringing DTMs closer to cradle-to-cradle sustainability models.

- Powder DTM Systems: Emerging powder-based DTMs now offer primerless adhesion on sharp edges and complex geometries, challenging liquid DTMs in factory settings where oven curing is feasible.

- Smart Additives and Functional Coatings: Additives that respond to mechanical damage, environmental pH changes, or moisture to activate protective functions, transforming DTMs into responsive protection systems.

New developments are also focusing on hybrid binder systems where epoxy-acrylic or silicone-acrylic combinations provide both mechanical strength and environmental durability. Research has demonstrated that combining fluorinated and acrylic segments in a latex particle can yield waterborne DTM coatings with gloss retention rivaling TGIC based powder coatings, extending use to architectural curtain walls and highway structures.

In parallel, cross-industry collaboration is promoting coatings tailored for emerging sectors such as renewable energy infrastructure. DTM coatings are being trialed for wind turbine towers, solar panel frames, and even battery enclosures, where durability, chemical resistance, and aesthetics converge.

There’s growing traction around the use of vitrimers in DTM—thermoset polymers that can be reshaped or healed at elevated temperatures, enabling repairable yet durable coatings. Their adaptability makes them promising for industrial maintenance where longevity and cost-efficiency matter.

Regulatory and supply chain pressures are also accelerating AI adoption. Coating formulators increasingly rely on predictive modeling to test hypothetical DTM formulations under different environmental and mechanical stressors. This virtual simulation cuts R&D timelines dramatically.

Finally, future DTMs are expected to integrate embedded sensor functionalities for structural health monitoring. This opens new pathways for smart infrastructure coatings that not only protect but also diagnose, enabling predictive maintenance.

These directions suggest a bright future for DTMs as a high-performance, smart, and sustainable solution for modern industrial and architectural coating needs.

Field Adoption and Market Expansion

The adoption of DTM coatings has expanded significantly across sectors beyond traditional light industrial use. The oil and gas industry has started evaluating high-performance DTMs for above-ground pipeline structures due to their simplified maintenance and fast return-to-service benefits. In construction and architectural metal markets, DTM coatings are gaining favor for steel cladding, handrails, support structures, and galvanized building frames where aesthetics and protection must coexist.

OEM manufacturers are also investing in DTMs as a viable solution to streamline operations. For example, equipment manufacturers are turning to DTM technologies to coat steel frames, enclosures, and components in one step, reducing labor and cycle time while complying with global VOC and HAP limits.

Notably, the automotive refinish sector is testing rapid-cure DTMs as primer-surfacers for commercial vehicle panels and underbodies, citing lower emissions and easier repair workflows. This marks a shift from DTMs being viewed solely as low-end coatings to viable, high-performing alternatives across complex use cases.

As performance validation and confidence grow, more specifiers and coating engineers are integrating DTMs into long-term asset protection programs. Coating specifications, once rigidly tied to three-layer systems, are being reimagined to include high-performance DTM technologies.

Technical Challenges and R&D Opportunities

Despite the progress in formulation and field adoption, Direct-to-Metal coatings continue to face several technical challenges that demand ongoing research and innovation:

- Substrate Variability: DTM coatings must adhere to a wide range of metal substrates—cold-rolled steel, galvanized steel, aluminum alloys, and weathered or oily surfaces. The differences in surface energy, oxide layer chemistry, and cleanliness all affect adhesion and performance. Developing universal adhesion promoters or self-adaptive polymers is a key research direction.

- Film Thickness Control: Applying a single-coat system at higher film builds (>100 microns) without sagging, bubbling, or compromising cure remains difficult, especially with waterborne chemistries. Advanced rheology packages and novel thickening agents are under development to enable smooth, sag-free high builds.

- Cure Speed vs. Pot Life: Two-component systems face the classic tradeoff—faster curing means shorter pot life. R&D is focused on latent catalysts and microencapsulated hardeners that extend working time while ensuring fast cure post-application.

- Long-Term Weathering Data: Accelerated weathering tests (QUV, salt fog, humidity chambers) simulate aging but don’t always capture real-world conditions. Long-term outdoor exposure data across climates is essential to fully validate DTM performance across all geographies.

- Sustainability Metrics and Certification: While many DTM coatings meet low-VOC standards, full sustainability assessment requires life cycle analysis (LCA), indoor air quality certification, and ingredient transparency. Emerging standards like Environmental Product Declarations (EPDs), Green Seal, and LEED v5 alignment are becoming key differentiators in green procurement.

These challenges represent opportunities for coating manufacturers and research institutions to collaborate on next-gen DTM materials that go beyond compliance to deliver multi-functional, environmentally conscious, and globally adaptable protective solutions.

Conclusion

From a niche convenience solution in 2019 to a mainstream, high-performance technology in 2025, Direct-to-Metal coatings have evolved significantly. Enabled by chemistry, inspired by sustainability, and driven by application needs, today’s DTMs are more than just a primer-topcoat replacement. They are a reflection of modern coatings innovation – smart, sustainable, and performance-optimized.

References

- UL Prospector Knowledge Center. (2019). The rapidly growing segment of direct-to-metal coatings. Retrieved from /9645/pc-the-rapidly-growing-segment-of-direct-to-metal-coatings/

- American Coatings Association (Paint.org). Technical papers and regulatory updates on DTM coatings and VOC regulations. Retrieved from https://insights.basf.com/home/article/read/acrylic-polyol-with-enhanced-performance-for-2k-pur-direct-to-metal-coatings

- BASF Insights. Technical briefs on high-performance DTM resins and field validation. Retrieved from https://insights.basf.com/home/article/read/acrylic-polyol-with-enhanced-performance-for-2k-pur-direct-to-metal-coatings

- Arkema Coating Resins. Product documentation and whitepapers on self-crosslinking acrylics and PVDF hybrids. Retrieved from https://www.arkema.com/global/en/media/newslist/news/non-global/countries/americas/20240402-arkema-american-coatings-show-2/

- Innovations in waterborne epoxy and polyester-polyol DTM systems. Retrieved from https://allnex.com/en/technologies/waterborne-resins/water-based-acrylics

- Digital formulation optimization and sustainability initiatives in polyaspartic systems. Retrieved from https://solutions.covestro.com/en/highlights/articles/theme/product-technology/pasquick

- Lamberti Surface Treatment. Trends in eco-friendly DTM additives and flash-rust inhibition. Retrieved from https://surfacetreatment.lamberti.com/insights/list-news/2025/ESACOTE-AC-C5609.html

- PCI Magazine (PCImag.com). Technical articles and product announcements for anticorrosion pigment and additive technologies. Retrieved from https://www.pcimag.com/articles/112434-a-graphene-enhanced-anti-corrosion-chemical-additive-for-solvent-based-paints

- Sherwin-Williams. Environmental Product Declarations (EPDs) and DTM performance disclosures. Retrieved from https://www.sherwin-williams.com/architects-specifiers-designers/specifications/sustainability

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.