Regulatory updates refer to changes and modifications made in existing regulations, laws, and guidelines that businesses must adhere to. Here, we are referring to coatings. They encompass information or announcements about updates in regulations that affect markets. These updates are crucial as they can materially impact compliance requirements and operational practices. Updates may be information pertaining to proposed regulations or changes in verbiage for clarification. As there is much literature about bio everything, there is similar quantities of information on regulatory updates. All you have to do is Google “regulatory updates” and whatever the specific and you will uncover a myriad of information. Whether coatings, adhesives, inks etc.

An example of this is in the comments from the ACA (American Coatings Association) to the California Department of Resources Recycling and Recovery (SB 54) in of how terms of “plastic” or “plastic polymers” are defined (Oct 15, 2025). Further, there are sections on revision of civil penalties and Court Hearings.

Additionally, there are ACA member webinars for the state affairs network making more than one state. October 21st was Connecticut, Florida, Oregon and Washington. These are typically given as updates by lobbyists that follow this state regulation changes closely, as well as an update by someone in legal. Top priority issues included PFAS, chemicals management packaging, extended user responsibility initiatives and other topical updates. The ACA publishes what will be covered and provides enough time to schedule to attend by Zoom. They typically are 1 1/2 hours long and follow the same format for each state.

On October 23rd a letter was sent from the ACA to the honorable John Curtis who is the chair for the subcommittee on chemical safety, waste management, environmental justice and regulatory oversight. This was a letter on Examining the Beneficial Use and Regulations of Chemicals. Senate-EPW-10.23.25.pdf This is just another way that someone is able to follow changing regulations; in this case for Pre-manufacturer notices (PMN), Significant new rules (SNURs), Risk Evaluations, etc.

In addition to the updates, the ACA has adopted a policy to ensure that other regulations are highlighted. PAR (proposed amended rules) 1122 solvent degreasers and 1143 consumer paint thinners and multi-purpose solvents Can be found on the South Coast AQMD AQMD – Home (Air Quality Management District).

The coatings industry is still focused on PFAS and after years have settled on regulations pertaining to VOC levels on coatings that are manufactured and sold in the States. There are other issues in the background which don’t really appear on anyone’s regulations but there is still work on the different chemistries. Hexavalent chromium is still considered extremely toxic and exists in military coatings. Its replacement with chromium +3 is not as effective in most cases. There are some surfactants that are used in various places and regulated by some countries and not others. I have found the general rule of thumb that regulations seem to occur in Europe first, migrate to California, Illinois, New York and New Jersey. People should be aware that a lot of the regulations occur when there aren’t legislative issues going on; i.e. elections. Most States and regions table the motions until after elections occur.

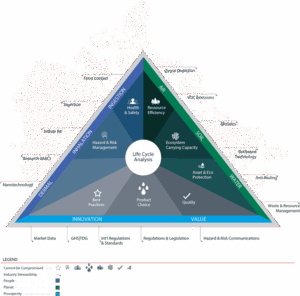

As can be seen by the above graphic, there is emphasis on the industrial coatings market since it has a large share of the total coatings market. People focus on the architectural segment but there are many other segments that are as valuable and which regulations affect more.

Simplify and streamline data collection, management, reporting and disclosure activities with UL 360 software for enhanced sustainability efforts. Learn more here!

Another area of focus is Paint Care. Retailers — PaintCare This has taken a while to become a fully-mandated paint stewardship program, but there are companies whose sole mission is to deliver quality recycled paint in a variety of colors and finishes. No longer is it a matter of finding something to do with returned paint, such as mixing it in with coatings that were used on federal penitentiaries as was done many years ago. In this case as in other market segments, a fee schedule was set up to make the program fair and equitable.

In Europe, the ECHA (European Chemicals Agency) has issued Version 6.0 (October 22, 2025) of its guidance on Annex VIII to the CLP Regulation, which regulates Poison Centre Notifications (PCN) and UFI (Unique Formula Identifier) labelling. All new and updated submissions must now follow the harmonized PCN format. Why it matters: For coatings formulators, every change in formulation, classification or packaging triggers a new notification. Non-compliance can block market access in the EU.

Several new CLH (Classification and Labelling Harmonization) propositions are open for public comment. Some include resin- or rosin-based substances relevant for binders and modifiers in coatings. Early awareness saves time and cost: anticipating potential reclassification helps avoid last-minute label and SDS revisions.

An excellent source of information can be found in ULTRUS™ Prospector® Knowledge Center; Navigating New Regulatory Currents in the Global Coatings Industry written By Ron Lewarchik and Vishakha Makode Sept 8, 2025.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).

) as the applications and development manager in Core R&D in the Coatings & Functional Polymers Group. He also managed the TS&D group for coatings while at Dow Chemical (1995-99) and held positions at Rhodia (Laboratory Manager, Latex & Specialty Polymers (1989-95)) and was the Development Chemist, exterior latex paints at Benjamin Moore & Co. (1979-89).