There are many ways in which artificial intelligence (AI) and machine learning (ML) can revolutionize the polymer industry:

There are many ways in which artificial intelligence (AI) and machine learning (ML) can revolutionize the polymer industry:

- Accelerating new material discovery, moving from slow “trial-and-error” to data-driven, efficient innovation in design, synthesis, and production.

- Predicting materials properties

- Boosting sustainability through less waste and energy

- Optimizing complex production processes (like temperature/pressure control)

- Enabling real-time quality control in production with machine vision

While Part 1 is largely the province of the large, well-established process automation companies – and in many ways represents an incremental improvement in past practice – Part 2 is very much “Blue-Sky” territory; the companies involved are often at the startup or research stage of their evolution and the field is fast-moving and volatile.

Part 1 of this two-part series looks at the more mundane topic of how AI is increasingly being used in production generally. In this regard, polymer manufacture and polymer processing are two chemical engineering processes which are broadly no different to any other.

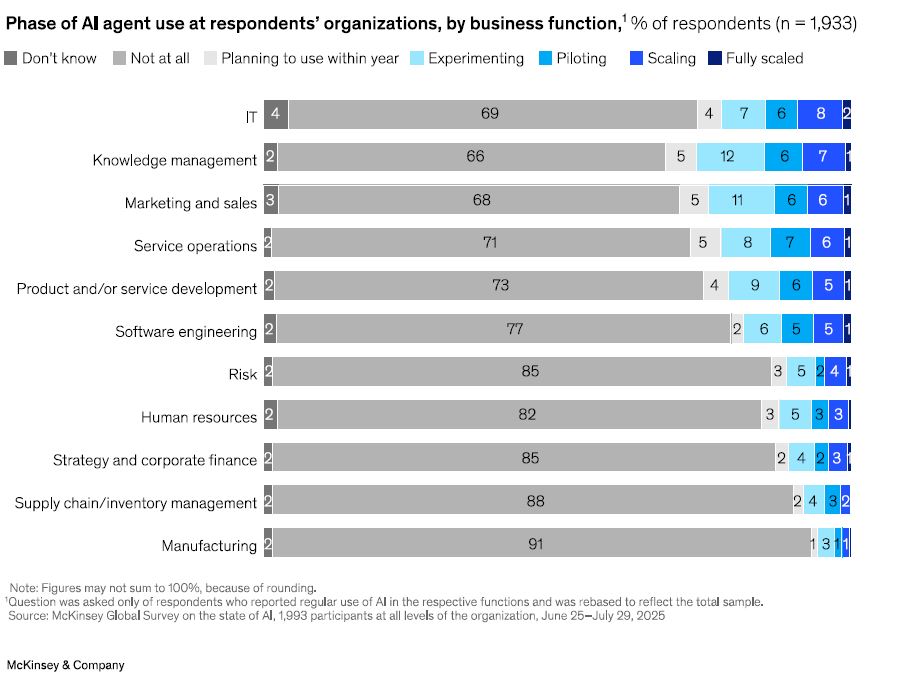

What the two areas have in common is that, even over the past year, AI has started to shift from being a mere assistant to a core driver of efficiency and innovation in polymer manufacturing. But equally, not all manufacturing companies are embracing AI with the same energy and enthusiasm: lest we should think that in 2025 the use of AI in manufacturing is as widespread as a casual glance at the media might suggest, Fig 1 shows the result of an international survey by McKinsey. This shows that in the manufacturing sector, 91% of respondents described their use of AI as “Not at All”! That said, most have begun to use AI somewhere in the organization, most at the early stages of scaling and capturing enterprise-wide value.

A recent MIT study found that 95% of businesses weren’t seeing a return on investment (ROI) from their generative AI spend. The study’s popularity seemed to confirm what many close to the technology felt to be true: it was difficult to implement, often unreliable, and disruptive enough to upend business processes and make things a mess.

These concerns may all be legitimate, but now a new study from the University of Pennsylvania’s Wharton School has found that 74% of businesses that measure the ROI from their generative AI efforts are already seeing a positive return and more expect to see a positive ROI within the next two or three years. “These results are more positive than I was expecting,” Wharton Professor Stefano Puntoni told Alex Kantrowitz of the Big Technology Podcast. “People are finding this technology is powerful, so it’s not just hype.”

Discover Material Selection with Prospector Premium, learn more here!

Challenges

But despite the benefits, challenges in adoption of AI persist, often at the business or enterprise level:

- Automation savings not tightly linked to board-level KPIs

- Integrating AI with existing legacy equipment,

- Low ROI realized and diminishing value delivered to date

- Value not measured in logical units an enterprise can appreciate

- Automation programs stuck in piloting or PoC scope

- Prohibitive cost of implementation and maintenance due to the increasing costs of niche tech talent and/or and the requirement for specialized workforce training.

- Avoiding technical debt across the complex ecosystem of different point solutions

- Questions around AI systems’ compliance with existing and emerging regulations

- The need for large, high-quality datasets for specific polymer types,

Specialist guidance available

Companies looking to take their first steps in AI-driven manufacturing may find valuable help from companies like UiPath. Originally founded in 2005 in Bucharest, Romania, UiPath is now based in New York, where its global headquarters is located.

This company has developed an automation platform that uses software robots (bots) and AI to automate repetitive, manual business tasks, allowing companies to streamline processes, reduce errors, and free up employees for more complex work, with features for everything from simple data entry to complex workflow orchestration and intelligent document processing. It’s known for its user-friendly, low-code environment, making it accessible to business users, not just developers, to build automations for areas like finance, HR, manufacturing, and customer service.

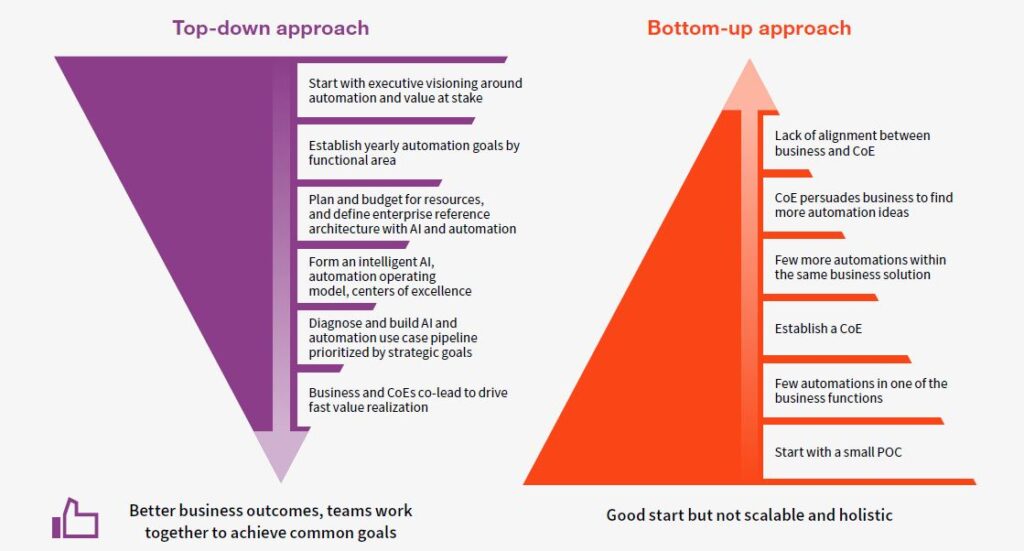

In its backgrounder “Turn-AI-potential-into-AI-results-8-steps-to-success-in-manufacturing”, the company cites the following eight key stages:

- Understand the business’ strategic problem statements

- Identify the top-down value at stake

- Verify the inside-out value potential

- Define the software and data reference architecture

- Envision the future of AI-powered automation

- Scale up and down the value chain

- Operationalize AI

- Build a holistic investment case on total cost of ownership and AI potential

AI in general automation

AI is identified as a key driver of growth and efficiency in the industrial sector, helping companies pursue sustainability goals. Installers of process plant and their component suppliers are already utilising AI for process optimization, quality control and predictive maintenance.

While AI is impacting the polymer processing industry generally, the primary approach of the major automation companies is the integration of general AI-driven automation systems into manufacturing lines generally, rather than offering a single, specific product line dedicated solely to “polymer processing AI”. These companies are providing the digital tools, automation platforms, and AI capabilities that companies in the polymer processing sector can adopt to modernize their operations, improve efficiency, and move towards more sustainable practices. However, in some instances, partnerships have been established between the generalist automation companies and smaller niche companies specialising in the polymer processing sector.

Process Control: Siemens industrial controllers, such as the S7-1200 PLC, are combined with AI-driven software in complex processes like injection moulding. Rockwell Automation’s Allen-Bradley control systems are widely used in the polymer processing industry, including injection moulding, for precise process control and can be integrated with advanced technologies, such as those by XanTec Steuerungs und EDV-Technik (now part of Dover Corporation), which specialize in control and automation specifically for polymer processing.. Schneider Electric integrates Artificial Intelligence (AI) into polymer processing through its open, software-defined automation platforms; the EcoStruxure suite assists in managing energy use and sustainability footprints. Mitsubishi’s Maisart (“Mitsubishi Electric’s AI State-of-the-Art Technology”) is designed to be lightweight enough to run directly on industrial controllers (PLCs) or specialized robots, such as the MELFA CR series, allowing for intelligent handling and sorting of polymer parts on the production line. Additionally, Mitsubishi Electric Research Laboratories (MERL) has been referenced in academic reviews concerning artificial intelligence and manufacturing science, which includes related areas like polymer processing.

Process Optimization and Quality Control: AI and machine learning (ML) are applied for real-time monitoring and control of polymer manufacturing processes. AI-driven machine vision can identify microscopic flaws and anomalies in polymer forming processes (e.g. injection moulding or 3D printing) that are invisible to the human eye. Using automated systems for process monitoring can improve reproducibility and reduce contamination risks. Machine learning algorithms can fine-tune parameters (such as heat, pressure, flow) in real-time, maximizing yield, minimizing energy, and reducing scrap.

In polymer manufacture, excessive heat can lead to side reactions and degradation. Prolonged reactions may increase impurities due to secondary reactions. Catalyst concentration too must be optimized to ensure efficient conversion while avoiding over-catalysis.

In 2025, the focus of Mitsubishi Electric is on “Smart Injection Moulding,” which integrates AI into injection moulding machines to monitor variables in real-time and thereby aims to improve energy efficiency and material circularity by optimizing the thermal profiles and cycle times of polymer melts. Its AI algorithms can automatically adjust processing parameters to compensate for fluctuations in polymer viscosity or environmental conditions, ensuring consistent part quality and reducing scrap. Similarly, Siemens ML models can analyse time-series data from extruders to forecast parameters like melt pressure, enabling more precise control strategies and moving towards zero-defect manufacturing. Schneider Electric provides open, software-defined automation platforms that utilize advanced control algorithms and real-time data handling to operate plants at peak performance.

Industrial AI: Siemens has partnered with Microsoft to develop the Siemens Industrial Copilot, an AI-powered assistant designed to improve human-machine collaboration and efficiency in manufacturing settings. Siemens’ software portfolio, including the Insights Hub, facilitates data analytics and the deployment of AI applications in an industrial context.

Equipment and Automation: sensXPERT, a Siemens technology company, AI and machine learning are used to evaluate polymer properties (e.g. degree of cure, viscosity) directly within the mould. This allows for real-time process adjustments to ensure product consistency and reduce scrap. Siemens has also acquired companies that specialise in the polymer processing and related markets, such as MAAG, to provide IoT-enabled technology for remote service and monitoring, which uses data for AI applications. Schneider Electric’s automation solutions have been implemented by MAAG (a specialist in polymer processing), to optimize the use of additives in plastics recycling.

Predictive Maintenance and Monitoring: Sensors monitor equipment health, allowing for repairs before failures occur, which minimizes unplanned downtime. AI can analyse sensor data to forecast equipment failure in machinery like extruders, preventing costly downtime.

One study in polymer extrusion utilized AI to monitor mechanical stress and wear of machinery components. The AI model forecast likely failure points, allowing proactive maintenance that lowered downtime by 20%. Dow Chemical employs AI-enabled predictive maintenance on its polymerization reactors, using vibration and temperature sensors to predict maintenance needs. This has resulted in a significant extension of reactor life and a 25% reduction in unplanned downtime.

The broader industrial controls market is seeing AI integrated into control systems, including those used in polymer processing, to develop advanced automation for improved operational efficiency and predictive maintenance. Siemens uses AI-based digital twins to to simulate, optimize and monitor industrial processes, including extruders and injection moulding machines. These systems use time-series analysis to predict melt pressure and detect potential defects before they occur, significantly reducing unplanned downtime. Siemens NX, for 3D modelling, and Tecnomatix, for plant simulation, are used to build these digital representations. Schneider’s EcoStruxure platform includes using AI-based tools for predictive analytics and real-time monitoring to enhance plant productivity and reliability. Rockwell’s Allen-Bradley hardware and FactoryTalk software depend on AI and machine learning (ML) for predictive maintenance and real-time anomaly detection in complex industrial environments. Mitsubishi is utilizing edge-based AI control loops to enable predictive maintenance for polymer processing equipment.

- In Part 2 of the series, we will look at the much more complex and advanced – and therefore challenging – potential of AI, taking general automation opportunities a stage further, or getting down into the fundamentals of designing new materials, fine-tuning existing grades and predicting their properties, often with an eye on their biodegradable properties and sustainability. More complex aspects of the production process are also to the fore, with the development of deep learning models to produce consistent product grades from complex, non-linear polymerization reaction dynamics. This area is sometimes referred to as Polymer Infomatics.

References

1: The State of AI: Global Survey 2025 (McKinsey)

2: Turn-AI-potential-into-AI-results-8-steps-to-success-in-manufacturing https://start.uipath.com/rs/995-XLT-886/images/Turn-AI-potential-into-AI-results-8-steps-to-success-in-manufacturing.pdf (UiPath)

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.